The range hood is one of the most useful appliances in the kitchen to keep the air in the room clean and fresh. Its performance directly depends on how correctly the pipe for the hood is selected. We will talk about what an air duct is like and the materials from which it is made, as well as what to look for when choosing a pipe in our article.

Without a properly selected duct, the extraction efficiency is reduced

Types of air ducts: advantages and disadvantages of materials

- It's not a problem. Today, there are many models from dozens of manufacturers. But what to do in the case when the ventilation duct in the kitchen is located away from the location of the stove? But it follows exactly above the stove. In this situation, you need a special pipe for a kitchen hood.

Exhaust pipes can differ not only in shapes and sizes, but also in materials

Pipes designed to remove air flow from the kitchen can be made of aluminum or plastic. Both of these options have their own advantages and disadvantages, which you should familiarize yourself with before buying a product. Let's dwell on this moment in more detail.

Aluminum

The corrugated pipe for the kitchen hood (popularly called "corrugation") is made of semi-rigid aluminum. Outwardly, it looks like accordion fur, which, if necessary, can be stretched to the required size.

Corrugated pipes are made from semi-rigid aluminum

Advantages. The main advantage of the corrugation is the ease of its installation, which is achieved due to the ability to bend the element at any angle. A pipe with various types of section is produced, which allows you to choose an option for any configuration of the hood. The material is able to easily withstand temperatures up to 250 degrees, which makes it resistant to melting and ignition.

If necessary, the size of the corrugations can be adjusted with ordinary scissors

Flaws. One of the main disadvantages of the corrugation is its unattractive appearance, which can spoil even the most sophisticated interior. The presence of many folds provokes an abundant accumulation of dust and dirt on the surface, which is very problematic to remove. It is also worth remembering that once stretching the corrugation to its entire length, it will be very difficult to assemble it back into an accordion. When reassembling the structure, the tightness of the connection may be broken.

Plastic

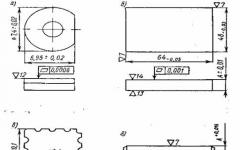

The plastic pipe for the kitchen hood is a smooth rigid structure, the section of which is made in the form of a rectangle or circle.

Plastic pipes are made with a round or rectangular section.

Advantages. Due to the smooth surface, plastic pipes do not accumulate pollution, and it is very easy to wash them with your own hands. Such designs do not make noise during operation, it is not difficult to disguise them. Plastic is strong enough and resistant to high levels of moisture that prevails in the kitchen.

To install a plastic duct, you will have to purchase additional corners and spare parts

Flaws. Rather high price in comparison with aluminum analogs. In addition, the installation of a plastic pipe is not as simple as that of a corrugation. In the process, it will be necessary to use additional adapters and corner elements that will help maintain the tightness of all connections.

Choice of duct size and diameter

The correct calculation of the duct pipe is as important as the selection of material and type of construction. An error in calculations can significantly reduce the productivity of the hood, increase the noise level during its operation, and increase the load on the functional elements of the device. All this can lead to damage to the hood and its costly repairs.

Incorrectly selected duct size will reduce the efficiency of the hood

In order for the duct connection to be successful, the following nuances must be taken into account:

- Diameter. When choosing the diameter of the duct, it is first necessary to rely on the diameter of the exhaust pipe. The pipe should not be smaller than it in size, an exact match is desirable. In the event that the ventilation duct of the house has a smaller diameter than the exhaust hole, then it simply does not make sense to install an air duct with a larger diameter.

The size of the duct may slightly exceed the diameter of the ventilation, but not be less than it.

The minimum indicator of this parameter is 80 mm. Due to the fact that the dimensional step is 10 mm (for example, there are options with a diameter of 90, 100, 110 mm), choosing the right material is not difficult. Most often in kitchens, exhaust pipes with a diameter of 180 or 200 mm are used.

- Length. The ventilation pipe should not be too long (maximum 3 meters), nor bent, because each turn of the pipeline at an angle of 90 degrees leads to a decrease in the overall performance of the system by 10%. If the bend exceeds 90 degrees, motor overload and improper air outflow may occur.

The more corners the connected pipe has, the lower the hood performance

When carrying out installation work, it should be remembered that the optimal length of the duct is 3 m. If you need a longer pipe, then remember that each additional meter in excess of the norm reduces the efficiency of the hood by 5-10%. If we talk about the optimality of the section, as well as the material, then it should be noted here that a round pipe with smooth walls is considered the most appropriate choice.

Duct masking options

In order not to violate the integrity of the interior and not to spoil the appearance of the kitchen, the question often arises of how to hide the pipe from the hood in the kitchen. There are several very elegant solutions.

- masking box. A decorative box will easily hide both plastic and aluminum ducts. To install it, the first step is to build a frame of metal profiles, corners and self-tapping screws. Fixing the installation to a wall or ceiling, the frame is sheathed with sheets of moisture-resistant drywall.

Thanks to a masking box made of drywall or plastic, the interior of the kitchen will remain complete