At the final stage of installation of any plumbing device, it is connected to a system of cold and hot water supply. At the same time, the mixer tap is an important connecting component. It must meet the highest quality standards, as it is responsible for an important function - uninterrupted water supply.

When buying components for connecting a mixer, be sure to consider them:

- wear resistance and reliability;

- ease of installation;

- quality of connecting sections;

- constructive performance.

Often, the connection of a plumbing fixture is not carried out in places convenient for this. Therefore, in order to ensure reliable operation of the mixing device without unforeseen surprises, it is necessary to think over the installation option in advance and select the parts suitable for this.

What are the types of mixer taps

The connection of the tap to the main pipeline can be carried out using different piping options:

- flexible;

- hard;

- bellows.

Consider the performance characteristics and design features of each type separately.

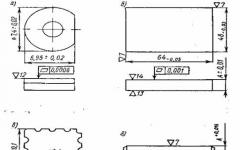

Hard eyeliner

Provides the most reliable faucet connection option. It is represented by metal pipes of small diameter, made of steel, brass or copper. One side of the hard connection is attached to the thread of the pipeline, the other is connected to the mixer using a threaded connection. Rigid eyeliner is able to withstand chemical disinfection of premises, high temperature loads, external mechanical influences of a certain force.

The advantages of a rigid connection of the device to the water supply system, subject to the requirements for the installation process, are:

- resistance to the development of corrosion;

- relatively easy installation;

- long service life (up to 20 years).

The rigid faucet connection can be connected to the water supply system in two ways: using special angle valves and connecting adapters or without additional adapters.

The rigid version of the liner is produced in a standard length, the value of which varies between 20-50 cm. The connecting thread can be represented by two options:

- ½ inch female union nut and nipple on one side of connection.

- M10 standard thread or ½ inch female flare nut on the other side of the connection.

A rigid version of the connection with a mixer can be seen in rooms with high traffic of people, in particular in clinics, hospitals, sanatoriums, boarding houses, schools, kindergartens, sports and recreation centers, etc.

Replacing external hard wiring is a simple operation that you can do yourself.

Flexible eyeliner

Today it is the most affordable and easiest option for solving the issue of connecting a faucet to the water supply system. Flexible wiring is represented by a rubber hose in a metal braid. Most often it is used for installation in private houses and apartments, as well as for household appliances that require connection to a water supply source.

The life and reliability of this component depends on the material from which the hose and braid are made. The metal braid provides external protection of the hose against mechanical loads, and also protects against the unpleasant consequences of internal hydraulic shocks in the system. It is capable of holding pressure up to 10 atm. and is made of thin threads of galvanized iron, aluminum or steel.

Two types of materials are used in the manufacture of the hose:

- high quality rubber;

- special non-toxic rubber.

The second important element of flexible wiring for a mixer is the attachment zone. On this section, on one side, there is a brass insert with a union nut, and on the other, a brass fitting. To ensure the tightness of the connections of the mixer and wiring, there are sealing rubber gaskets. Flexible wiring along the length is produced by manufacturers in sizes from 30 to 200 cm. This allows it to be used for mounting both on a rack and on a bathroom side.

Simple at first glance, a flexible connection is a rather complex connecting element, produced using high-quality materials using the most advanced technologies. Provided the production of flexible wiring from excellent quality materials and stainless steel threads, it can maintain its performance for up to 10 years. High temperatures, sharp twisting during installation and kinks can bring it out of working condition. Currently, flexible wiring for faucets is the most common solution.

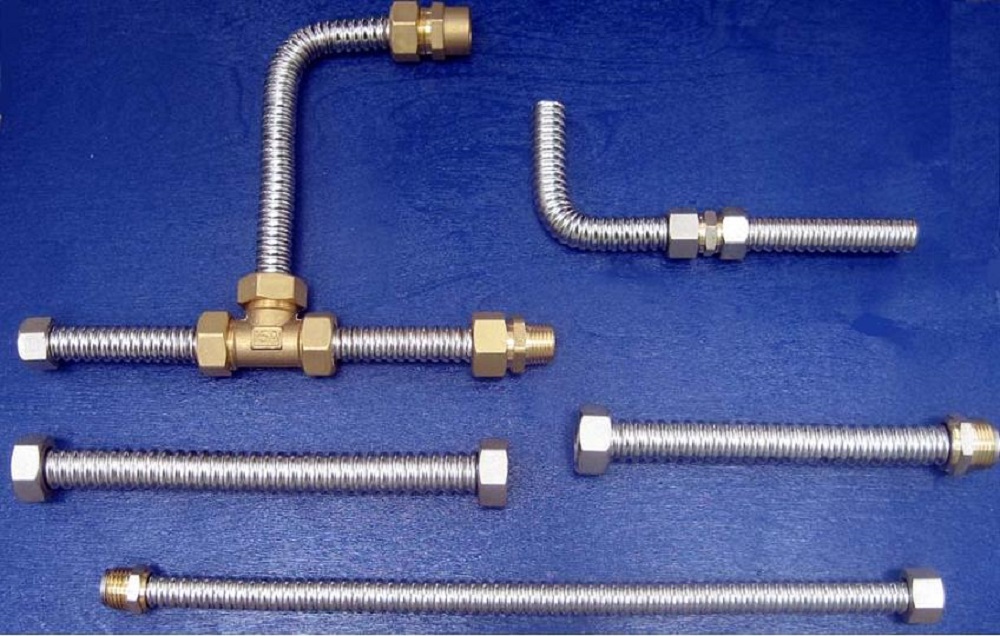

Bellows connection for mixer

It is represented by a corrugated metal hose made of stainless steel and brass union nuts, which act as termination elements for connection. Compared to rubber analogues, bellows products are produced using an innovative technology, which consists of three main stages:

- Rolling stainless tape.

- Seam welding by argon arc or laser welding.

- Corrugation of a metal hose.

The bellows faucet connection option is the latest solution in plumbing fixture connection, providing excellent performance of the wiring system:

- Long and reliable operation at elevated temperatures (up to 250 ° C).

- High wear resistance.

- High resistance to oxygen diffusion.

- Resistant to sudden compression and bending during installation.

- Corrosion resistance.

- Withstand certain temperature changes.

- Resistance to aggressive environments.

- Easy to install bellows type faucet wiring.

- The corrugated state allows the wiring not to change the flow area during bending.