If you have held a drill or hammer in your hands at least once in your life, you already have a chance to independently create a convenient and comfortable place for water procedures. What is it for?

First, you will gain the respect of your friends and neighbors, to whom you will be proud to show off your creation. Secondly, your cabin will be in a single copy - the shape and size you need. And finally, thirdly, if you do everything right (without causing a flood or destroying partitions), you will save money. You are already saving 5-7 thousand rubles on installation alone!

Shower cabins are manufactured made of brick, tile or fiberglass. In this section, we will take a detailed look at the advantages and disadvantages of all these materials.

Made of brick

These cabins are usually strong and durable. Unlike glass walls, brick walls are difficult to break or damage. In addition, an opaque cabin made of such material will be a suitable solution if you plan install it in the yard private house or cottage. In this case, you don’t have to worry that someone will see you taking a shower.

The disadvantages include significant weight designs. It is not advisable to install such a cabin in a room with unreliable ceilings.

From tiles

If such a design is made professionally, it can become a real decoration for your home. Now there are so many different tiles that you can revive antique frescoes right in your bathroom or create the color of a Turkish hammam using blue and white tones.

The disadvantages of a tiled cabin are complexity of the manufacturing process. You need to be able to work with tiles, carefully laying out each tile.

Made from fiberglass

This is a classic design option. Fiberglass has been used by manufacturers for a long time and is quite suitable for creating a country shower. This durable material that is highly moisture resistant.

A booth made of this material will weigh much less than a tile booth, so it can be installed even on the upper floors of a house or cottage. At the same time, fiberglass wears out a lot with frequent use and may crack or break from pressure and accidental impacts.

Along with fiberglass, durable tempered glass can be used. This material is less practical than fiberglass. But glass looks more expensive and presentable.

Made of wood

This style option will fit perfectly into the interior of a country house. Wood is an absolutely safe, clean material. If you decide to make a wooden shower, you it will be necessary to carefully treat the wood with water-repellent agents.

In the production of showers many people completely abandon the sashes, doors and partitions. Such models can be installed both outdoors (used as) and indoors.

Required tools and materials

Before you make a shower stall yourself, you need to draw a plan, take measurements, draw up an estimate and prepare all the necessary materials and tools.

What do we need to know before starting work?

- Place, in which the structure will be installed.

- Form– round, square, rectangular.

- Pallet dimensions. If the room allows, make the tray spacious enough to make it convenient for you to shower in the future.

- Structure height. You can move the booth to the ceiling or leave free space for additional ventilation and quick drying.

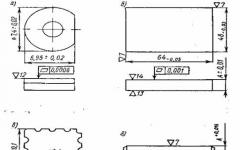

The standard dimensions of the cabin are 100x100 centimeters, but you can vary them as you wish. Don't forget to consider the thickness of the building materials you will use to build the cabin.

For construction we will need:

- Brick (silicate or masonry) for the pallet.

- Cement.

- Metal grid.

- Waterproofing mixture.

- Drill.

- Putty knife.

- Paint brush.

- Roulette.

- Water or laser level.

- Plaster beacon.

We build a pallet for the structure

The first steps in building a shower cabin with your own hands at the dacha or in a private house is installing a tray. We offer three options to choose from.

Brick

- Determining a place for water drainage. We bring the drain pipe to the sewer and install a drain hole. It can be located in the center of the pan for uniform water flow.

The height of the drainage channel should be about 20 centimeters(from the floor surface). We thread the drain into a metal pipe and secure the pipe to the floor using clamps.

- We treat the floor and walls with a waterproofing mixture, which will help prevent the formation of mold when using the shower stall. Apply the mixture using a simple paint brush.

- Using bricks and cement mortar we lay out the contours of the future pallet. As we wrote earlier, you can choose any shape of the pallet - semicircle, square or rectangle. It is most convenient to work with a square shape.

- We lay a metal mesh around the perimeter of the pallet. It will help ensure the necessary strength of the entire pallet structure.

- We lay out the entire surface of the pallet with bricks. Fill the top with screed. When filling with screed, it is necessary not to damage the drainage channel. After filling, it should protrude several centimeters above the floor level. We also need to make a slight slope towards the drainage channel so that during operation water does not accumulate in the pan.

- We wait a while for the screed to dry. Then pour the leveling mixture onto the future pallet. We complete the finishing with ceramic tiles or other materials.

Tiled

Construction of a pallet from tiles begins on the same principle as brick construction.

- We determine a place to drain the water and install a drainage hole and connect the sewer system.

- We treat walls and floors waterproofing solution. After completing all the work (before finishing), we also additionally process the circumference of the drain hole.

- We lay out the edges of the future pallet of bricks.

- We place a metal mesh at the bottom of the pallet. Then we install construction beacons and pour a screed from a solution of cement and crushed stone.

- Lay out tiles or mosaics. Treats joints between tiles with grout with waterproofing properties.

Sloping floor

A cabin without a tray is a very interesting solution for decorating a bathroom in a private house or country house. Such a cabin suitable for families with elderly people for whom it can be difficult to step over high sides. Also, showers without a tray, when properly designed, look very stylish and modern.

The disadvantages of such a cabin include the fact that it design should take place simultaneously with the renovation of the entire bathroom. If you've already done your bathroom floor, you'll find it very difficult to avoid a difference in floor level between the shower and the bathroom.

The most important point is the organization of the drain hole. It must be done at a slight slope so that water does not accumulate in the cabin. Also, as an alternative to the drain hole, drain grates can be installed around the perimeter of the cabin.

Wall installation

The walls can be made of brick, tile, fiberglass, natural or artificial stone, wood. We'll consider the most popular option is fiberglass walls.

If you are making a square indoor shower, you will only need to install two walls. When installing the pallet, we already took the necessary measurements and indicated the desired height of the cabin. We also need determine the location, in which we will place the mixer and watering can.

If you are making a square indoor shower, you will only need to install two walls. When installing the pallet, we already took the necessary measurements and indicated the desired height of the cabin. We also need determine the location, in which we will place the mixer and watering can.

Once again we check the accuracy of the measured height for installing the walls using a level. We take a drill and drill holes for fastening the profile. Screw the profile to the walls.

We insert the fiberglass walls into the prepared side panels on the wall. Fixing the side panels using special fasteners. We install the sliding door into the prepared profile. We carefully seal the shower stall.

Connection to water supply and sewerage

Connecting the water supply to the shower cabin is important and technically complex process, which is best left to professionals. If you have experience working with drainage and sewerage, you can perform the installation yourself.

In this article we will briefly talk about this; find out more details from the special detailed material.

In this article we will briefly talk about this; find out more details from the special detailed material.

We lead it to the wall near which the shower stall will be located. Additionally can be installed, which in case of an emergency can stop the water supply.

If necessary install– they will not only improve water quality, but also help increase the service life of the water supply system.

We connect the parts of the water supply using flexible hoses and plastic pipes. Carefully tighten the hoses. We install the shower head and check the serviceability of the water supply system.

The connection of the cabin to the sewer occurs at the time of installation of the pan. If the cabin is in the bathroom, we connect it directly to the waste riser. If there is no riser nearby, install a sump pump.