Sharpening a knife correctly by hand is quite difficult. It will take some time to develop the habit of maintaining a constant sharpening angle, which is not at all easy. A knife sharpening device can make the task easier. There are factory options. But for good copies you have to pay a couple of hundred dollars, and this is clearly a lot. Good news The fact is that these devices are easy to make with your own hands. Moreover, many homemade knife sharpeners are no worse in functionality than those from famous manufacturers, but they are many times cheaper.

Knife sharpening basics

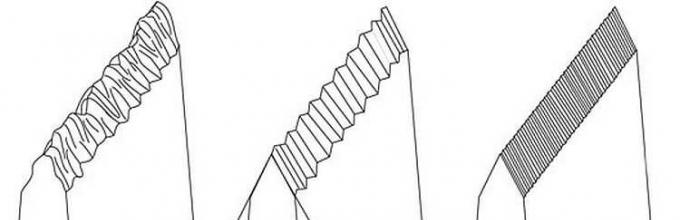

Knives have different uses and there are even several of them in the ordinary kitchen. There is one for slicing bread and other soft foods, and one for cutting meat, chopping bones, and other hard objects. And these are just household ones. But there are also those who take them hunting and fishing. If you look closely, you will see that they all have a different sharpening angle (this is if they have not already been sharpened at home). It is the sharpening angle that is the most important characteristic, which is determined by the purpose of a given blade.

At what angle

The sharpening angle is determined based on the main area of application of a particular blade:

This general recommendations, introduced based on many years of experience. There are, however, options: some blades have several zones with different sharpening. This makes them more versatile, but the difficulty of sharpening increases many times over.

From the above it follows that the device for sharpening knives must be able to set the required sharpening angle. And this is the main difficulty in its design and manufacture.

What to sharpen

To sharpen knives, sharpening stones of various grain sizes are used. They are conventionally divided into coarse, medium and fine. Why conditional? Because in different countries The grain size has its own designation. The most convenient classification is by the number of grains per unit area. It is expressed in numbers: 300, 600, 1000, etc. Some companies also use English terms. Here is an approximate division:

In addition to grain size, sharpening stones are also distinguished by their origin: some are of natural origin (slate, corundum, etc.), some are ceramic and diamond. Which ones are better? It’s hard to say - a matter of taste, but natural ones wear off faster and are rarely fine-grained.

Natural ones are soaked in water before use or simply moistened with it. They absorb water and, during sharpening, an abrasive paste is formed from water and separated abrasive particles on the surface, which increases the efficiency of sharpening. For the same purposes, you can use a special little (honing oil) or a mixture of water and soap (whichever you prefer). In general, you should try all these options with each sharpening stone and choose the best one.

The shape of a whetstone for sharpening knives is a block, and it is desirable that its length be much longer than the length of the blade - it is easier to sharpen. Bars with double grain are convenient - coarse on one side, finer on the other. To sharpen knives for ordinary purposes, it is enough to have two bars with medium grain (different) and two fine ones (one can be very fine).

Manual sharpening procedure

A device for sharpening knives only makes it easier to sharpen the edge, so knowledge of manual sharpening techniques is mandatory. Without them, it is impossible to sharpen a knife correctly.

The procedure for sharpening knives is as follows:

At this point, we can assume that sharpening the knife is complete. Some people are still finishing the edge on the old belt. A piece of belt can be secured to a wooden block (glued, not nailed), rubbed with goyi paste. Then pass several times alternately with one side or the other, but turning the cutting edge back. This way the last grooves left by the abrasive are polished and the belt is not “cut” in the process.

How to make a homemade knife sharpener

All homemade knife sharpeners solve the main problem - they allow you to accurately maintain a given angle of inclination of the block to the blade, which is very important for obtaining a good cutting edge. There are very simple devices, and some are a little more complex, but they allow you to work with greater comfort. Choose according to your taste.

Some of the options are from improvised means

Simple device for sharpening knives

Essentially this is a holder for sharpening stones. Everything is elementary: two triangles made of wood, which are connected by pins with wings. A block is clamped between the corners at the required angle. You can set the angle using a protractor, a special program on your smartphone, or using the rules of trigonometry (right triangle).

Knife sharpening device - abrasive holder

When sharpening on such a device, the knife must be kept pointed strictly vertically at all times. It's much easier than holding it at a certain angle.

The same idea has another embodiment: on a reliable basis, make movable holders into which bars are inserted and secured in the desired position. The corporate prototype is pictured below.

A homemade device for sharpening knives is made of wooden blocks. It turns out to be light, so that it does not move from its place, it needs to be fixed with something. To avoid holding with your hand, you can use clamps.

Rotating holders allow you to set a given angle, and then fix it with the help of “wings”

Such a device for sharpening knives, of course, makes the work easier, but it is still quite difficult to maintain the angle: you must constantly control the verticality of the blade. Such a habit can be developed over time, but starting is difficult.

Device on wheels

An interesting version of a manual knife sharpener with a fixed block and a wheeled cart on which the knife is mounted. It is made on the basis of sharpeners for knives, chisels and planes. This device also works well with a knife, but you need to get used to sharpening a rounded edge.

In this version, as in manual sharpening, the block is stationary, but the blade of the knife, mounted on a movable trolley, moves. The angle is set by the height of the bar relative to the platform on which the blade is mounted. The peculiarity of this device is that the table must be level. This could be a countertop made of natural stone, you can put glass on a regular table.

In the version presented above, the angle changes slightly, which is usually sufficient for sharpening similar types of knives - kitchen knives, for example. If necessary, the design can be improved by adding holders (pictured below).

All this is implemented very simply, as it resembles a regular construction set: planks with holes in them, everything is assembled with bolts and screws.

There is also a device to ensure the immobility of the block.

The advantage of this whole design is that it is easy to unfold the knife while maintaining perpendicularity on the rounded area, and it is also very easy to handle on the other side: you need to turn the cart over. For this purpose, four pairs of wheels were made.

Homemade manual machine for sharpening knives

Slightly more complex and much more convenient homemade devices, which are made on the basis of well-known branded devices. They have an adjustable platform on which the knife is fixed. The site is set at a given angle. The block is mounted on a movable rod attached to the stand.

Self-made devices in some ways repeat the design presented above, but there are some differences. There are many options. Let's give some.

Option one: a fixed platform on which the blade is fixed

This device is made from leftover laminate (can be used), two steel rods with a diameter of 8 mm and a movable fastener.

This design has a fixed base, to which a platform with a knife lock is attached on regular hinges. The near edge of the platform can be raised at some angle convenient for work. But otherwise she is motionless.

On a vertically mounted steel rod there is a movably mounted latch, in which a loop is attached to the side. A rod is inserted into it, on which the block is fixed. This loop is simple, but not the most The best decision: there is no rigid fixation, which means the angle will “walk”.

Particular attention should be paid to the bar lock. An emphasis is placed on the rod at some distance from the edge (about 30-35 cm). This will be a permanent fixture. The second one is made movable; it is fixed after installing the bar using a screw and a thread cut into the body of the holder. The second option is to cut a thread on the rod and tighten the installed bar using a nut.

Knife holder - one or two steel plates mounted on a movable platform. They are fixed movably using screws and wings. Having loosened the fasteners, insert the knife blade and clamp it. It is very difficult to move it. Then, installing a pin with a fixed bar in the loop, adjust its height so that the required angle is set.

You can, as in the photo, make templates with the required angles and ensure that the planes match. After the crossbar is secured, you can work - move the bar in the desired direction.

This device for sharpening knives works well, but you can only move the abrasive along the blade when sharpening a kitchen knife. Classic sharpening - movement perpendicular to the cutting edge. This can be achieved on the straight part of the blade. If the blade is short, this will be almost perpendicular, but on a rounded part on a fixed holder this cannot be done. And all such devices “suffer” from this drawback. Once again: they are an excellent option for sharpening kitchen knives (below is another good option from the same series).

Option two: with a movable platform and a magnetic holder

In this version of a homemade device for sharpening knives, the problem of previous sharpenings is solved. Here the frame remains motionless, which sets the angle of movement of the bar. The bar holder moves freely along a guide set at the desired angle. The knife is mounted on a movable table. You can, as in the presented version, make a magnetic holder, or you can make a regular one from a metal plate and “lambs”. Move the table so that the movement of the abrasive is perpendicular. Actually, everything is in the video.

One clarification: in this case it is very important that the surface on which the table with the attached knife moves is horizontal and level. You can put glass or use a polymer tabletop (marble will also work).

Every man in the house would benefit from a convenient sharpening machine. After all, the owner is often judged by how sharp this kitchen tool is.

There are many techniques for sharpening knife blades. For example, for a process carried out at home, only a turning block or ready-made devices with an angular gap shape.

To adjust expensive hunters' knives, European manufacturers produce devices in the form of solid bars, the basis of which is a high-strength alloy.

This article will describe how to make a machine for sharpening knives with your own hands.

Why do knives get dull?

What is the reason why a knife becomes dull when cutting? This can be explained by the fact that the cutting edge is negatively affected by abrasive particles that are present in the material being cut. For example, they are present on vegetables and paper. In simple terms, the blade is subject to gradual wear.

The next reason is the inability to hold the blade in the desired position all the time. Any trembling of the hand causes the knife to tilt, which entails a lateral load.

Sharpening technique

The sharpening technique consists of unified, but at the same time quite labor-intensive methods. The main task is to eliminate damage to the blade. It should be noted that for many, such a procedure as sharpening knives provides a good mood and peace of mind.

The basic rule when this process— maintaining a precisely specified constant angle. No force required here. The main thing is that the block and blade meet at a certain angle. This is the basic rule of the sharpening technique.

What needs to be done to maintain a constant angle?

In order for the angle to have a constant indicator, there are two ways. The first is to acquire the sharpening skill. The angle indicator can be controlled using a regular marker. They should paint over the connections and, after several sharpening cycles, see how well the paint is preserved. If it is worn unevenly, then the blade is not processed well.

If the knife being sharpened is decorative, then you should seal the blade with tape so that only the cutting edge remains open. Even if you misdirect your hand, there will be no scratches on the blade.

An important point is that the direction of the blade along the block is perpendicular to the edge at the points of contact. This is actually quite difficult to do. It is acceptable for the angle between the edge and the blade to be less than 90 degrees. But when directed along the cutting edge, this indicator is not suitable.

The abrasive particles of the stone can leave grooves on the blade that will never be sharpened, but will play a positive role when cutting. If the grooves are oriented along the cutting edge, then they will be of no use during cutting. The worst thing is that the cutting edge may break off altogether.

It is important that the bar is long. It should be one and a half or two lengths of the blade. It is allowed for the diamond block to be somewhat shorter, as it grinds faster and better. Its width does not play a significant role. If it is wider, then it is more convenient to work on it and there is less chance of the blade moving beyond the limits of the device. This may damage its side surface or the blade.

There are homemade devices for sharpening knives different designs. All that is required from the manufacturer is the availability of the necessary material and skills in working with tools.

The operating principle of such a device as manual machine To sharpen knives with your own hands, you need to hold the knife blade in a vertical position and drive it along a block fixed at the desired angle. This is much easier than placing the sharpening stone horizontally and holding the knife at the desired angle.

In order to make a machine for sharpening knives with your own hands, you need a piece of laminate, a wooden strip, sandpaper and a pair of bots with wings. Chipboard or plywood can serve as a replacement for laminate.

To make a knife holder, you need to cut off some of the material. To prevent the block from touching the holder when sharpening, you should sand its edge at an angle using sandpaper.

It is necessary to mark and cut off the top of the vertical post, which will serve as a support for the block. The angle chosen is half that at which the knife will be sharpened. For kitchen knives, it is recommended to take an angle of 10-15 degrees.

A machine for sharpening knives with your own hands, the drawings of which are prepared in advance, requires the correct calculation of the length of the base of the racks. Please note that the height indicator will be affected by the subsequent installation of the transverse support. After this, all parts are trimmed and the edges are cleaned.

Holes are marked and drilled in the base and plate for pressing the bolts that secure the blade. When marking, the distance of the holes from the edge of the base is maintained. This is necessary for the versatility of the device, since all knives have their own width. The pressure plate is secured with bolts.

Vertical posts are secured with screws. It is also taken into account that the load on the bottom is small. In this case, it is better to resort to using thermal glue. The horizontal crossbar is attached in exactly this way. The sharpening device is almost ready. All that remains is to make the block.

To make it, a strip of the required length is cut. Sandpaper with the required abrasive size is glued to one edge. To optimize the result, you can resort to making several bars with different indicators graininess. The range P600 - P2000 is considered the best. To protect your hands from cuts, you need to screw the handle on the top side of the rail.

In the end it turns out homemade machine for sharpening knives with your own hands, characterized by high functionality and practicality. When working, the device rests against the edge of the table, which is quite comfortable when using it.

There are also other types of machine for sharpening knives with your own hands. In this case, it is based on an M8 threaded rod. Two large washers and nuts are used, which serve to hold a bar 200 mm long.

Covers the thread. A pair of paper clips serve to secure the guide stand at the desired height. This ensures smooth adjustment of the sharpening angle. The base is made of timber, the thickness of which is 40 mm. It is supported by hand.

How to sharpen jointing knives with your own hands

Every owner who has a plane or jointer, I've probably encountered the problem of sharpening their knives. It is expensive to purchase new ones periodically. Knives can be easily sharpened with your own hands. In this case, specialized machines are used, or if it is used constantly, it would be better to make a machine for sharpening knives with your own hands.

Do-it-yourself machine for sharpening a jointer knife

To sharpen a jointer knife, special sharpening equipment is used. The machine for sharpening knives with your own hands has a compact size. It can be installed in a garage or on a personal plot.

Many people are interested in how to make a knife sharpening machine with their own hands. To make a device you need to find certain parts. Perhaps similar spare parts are lying around in your barn or garage. They can also be purchased via the Internet.

A machine for sharpening jointing knives with your own hands consists of:

- faceplates;

- table;

- engine;

- vacuum cleaner;

- casing.

The first thing you should do is find the faceplate. This is the most important component of future equipment. She is the one responsible for the sharpening process. The jointer knives are narrow, and the faceplate guarantees complete and safe sharpening. You will have to buy this part new, but the rest can be used even as old ones.

It is better to purchase faceplates of German or American production. The average cost of a part is 25,000 rubles.

The next step is to find a motor whose power should be 1-1.5 kW. There is no need to buy it. Anyone will do, even old ones washing machine. But everyone probably has a table, a casing and a vacuum cleaner.

Main stages of device manufacturing

When the table is selected, the engine is fixed directly under it. A faceplate is attached to the moving part. The engine must initially be equipped with a button that turns the unit on and off. It should be conveniently located.

For reliable protection the faceplate is covered with a square-shaped casing with one corner cut out. It is this area that needs to be sharpened.

A hole of the same diameter as the vacuum cleaner hose is made on the lower surface of the table in the sharpening area. The presence of a vacuum cleaner is not essential, but it is advisable to install it. It removes unnecessary dirt from blade processing.

What do you need to know?

Mounting the engine under the base of the faceplate is not a requirement. You can make sure that the parts are connected using a belt. In this case, the design will be more complex.

A do-it-yourself jointer knife sharpening machine is also suitable for saws and axes.

Ice screw sharpening

The sharp knives of the ice drill enable the fisherman to quickly make holes in the ice of reservoirs. However, over time, any cutting tools become dull and require sharpening.

For fishermen, a high-quality ice auger is a great source of pride. Often, true competitions on the speed of drilling ice holes are held on reservoirs. And victory does not always smile on young and strong fishermen who are armed with imported equipment. There are times when experienced fishermen, equipped with simple Soviet-made tools, emerge as winners in the competition. The reason for the high hole drilling speed lies in the good sharpening of the knives and the correct settings of the device. Beginner fishermen, having bought new Swedish devices, do not even have time to blink an eye before their knives become dull. Tiny grains of sand and pebbles in the ice contribute to the formation of chips and gouges on the blade.

Sharpening of devices is carried out by the most different ways. Many of our ancestors did not even know what professional sharpening was. In most cases, sharpening was performed using hand-made devices.

Homemade ice drill machine: what will you need to make it?

To make a device such as a knife sharpening machine, you will need two strips of steel, the thickness of which is 4 mm, the width is 60 mm, and the length is 200 mm. A spring from a car is often used as a strip. But it is very difficult to bend.

Progress

First you need to make the device case. The steel strips are bent in such a way that the chamfers of the knives pressed to the ends of the arc are not only parallel, but also in the same plane.

After making an arc from the same steel strip, a pressure plate is bent, which serves as a clamp for the knives being sharpened

Holes for M12 or M14 bolts are drilled in the body and pressure plate. Having tightened the body and the pressure plate using a bolt and nut, we clamp the knives between them and check the strength of their adherence to the surface of the end of the emery circle.

If the knives are not located at the required angle (the chamfers do not fit exactly to the circle), then the device is modified by bending the body arc to the appropriate level. If the knives are positioned correctly, then the structure is disassembled, and stiffeners are welded to the body arc on both sides.

Sharpening knives is best done on a knife that rotates horizontally. In this case, when wetting the knives with water, the latter remains on the blade and stone longer, ensuring their safety. Dip knives in water frequently. This will help prevent the steel from overheating.

Disadvantage of the device

The disadvantages of the device include the impossibility of sharpening knives with different cutting chamfer angles. But each ice drill manufacturer offers its own models. In this case, a universal device is suitable.

Making a universal device for sharpening an ice drill

The universal design allows you to sharpen knives at any cutting edge angle. By smoothly changing the angle between the arms of the unit, on which the knives are fastened with screws, you can fix the desired position of the knives in relation to the plane of the grindstone.

To make this device, you need to find a door hinge with minimal play, as well as an M8 or M10 screw with its own nut. Holes are drilled in the canopy arms. Their diameter is 6-7 mm (for attaching knives to them with screws).

A fixing plate with a slot for a fastening screw is made from a steel strip, the thickness of which is 3 mm. The plate and screw are welded to the canopy arms.

It happens that knives are sharpened, the location of the holes does not correspond to the holes in the canopy. In this case, additional holes are drilled in the arms for non-standard knives. In this case, the device has greater versatility.

How are planer knives sharpened?

Equipment such as planers and surface thicknessers can often be seen in country houses. Through them, raw lumber is brought to the desired state. The knives of these devices, like any other, become dull. If you use them often, then the best solution would be to sharpen your planer knives yourself. To make sharpening equipment at home you will need various materials: metal, aluminum or wood.

A knife holder can be made from wooden block. By making 45-degree cuts with a circular saw, you can sharpen the knives with a belt sander or a large whetstone. If the latter is not available, then sandpaper is attached to a smooth surface made of metal, wood, chipboard or glass.

Knife holders can be made from scrap materials. The optimal solution will be the use of metal corners that have an indicator of 90 degrees. When placing two knives on the sides, the sharpening angle of each will be 45 degrees. Using screws, you can secure the knives with a second corner.

Almost every person in life is faced with the question of sharpening knives. After all, any knife, regardless of its quality, sooner or later becomes dull. Therefore, the blade must be carefully maintained.

In stores today you can choose any sharpener from a huge variety.

What types of sharpening stones are there?

In general, there are several main types of such devices. Namely:

Oil-based, on the surface of which there is oil, specifically to save material.

Water, similar to the previous one, but water is used here.

Natural, industrially processed.

Artificial, made from non-natural materials.

Rubber, extremely rare. Completely inconvenient to use.

Nuances in the matter of sharpening

Every knife sharpening has its moments.

For example, Japanese self-sharpening requires special attention from a fairly experienced specialist, since Japanese look steel is quite brittle. To sharpen them, manufacturers recommend using different water stones with different grain sizes.

Housewives use store-bought sharpeners for sharpening. When using several knives, their sharpness remains longer.

But this is very important, even though it takes a lot of time and effort.

How to sharpen knives correctly?

For this it is necessary to create special conditions. Thanks to them, the knife will remain sharp for a very long time.

Therefore, it is important to choose the right angle at which you will sharpen your knives. According to the basic rule in this matter, than smaller angle, under which the knife is sharpened, the stronger the cutting edge will be.

It is important not to forget that the next sharpening depends on the maximum sharpness. The sharper the knife, the faster you will have to sharpen it. At the same time, making it “workable” again will be much more difficult.

Why do they sharpen knives?

The purpose of sharpening is to restore the sharpness of the blade. To do this, take care of the correct sharpening angle. That is, it is necessary to restore the previously specified angle, which complies with the standards from a technological point of view.

To check how well the sharpening is done, cut the material that is cut by the blade of this particular knife. If the material is cut simply, you will do everything absolutely correctly.

Possible problems during the sharpening process

In order to choose the right angle correctly, it is important to have some experience, without which it is quite difficult to cope with this issue. And even more so if there is no special equipment for this.

After all, if you hold a knife with your hands during the sharpening process, it is quite difficult to achieve its ideal “sharpness” as a result.

How do you sharpen knives at home?

Sometimes it happens that the knife needs to be sharpened quickly. A block of wood, a hacksaw, sandpaper, a ceramic plate, a chisel, etc. may come in handy here.

And there are even those who can sharpen them on a foundation made of cement and sand. But this method is not recommended at all. After all, there are many others and more proven ones!

The best of all is to make homemade device. This is not only convenient, but also hardly distinguishable from the factory one.

How to sharpen a planer knife

Knives of this type can be handled by an experienced professional craftsman who has not only knowledge, but also skills in this matter. The process is actually quite complicated.

At the same time, it is quite difficult to find equipment for sharpening such a knife in a simple store. You should know what will help here modern instrument, in which you can set low speed with water cooling.

You need to use a new stone with a flat surface. It will be the best aquatic view stone

Moreover, without having certain experience and skills in sharpening planing knives, you can also contact a service station, which probably has equipment such as a sharpener.

Electric grinders, or, as people say, emery stones, are collected in a great variety from everything that falls to hand; they are often made from motors from washing machines.

I also decided to make myself a homemade machine for drill sharpening, knives, etc. I have a Chinese sharpener, but its quality 😥 well, you understand...

Making such a machine turned out to be one of the easiest things to do :)

Because:

- I had extra engine at 1370 rpm and 370 watts.

- I didn’t order an attachment for placing a grindstone on the shaft from a turner, such attachments are sold on our market - just know the diameter of the motor shaft and you can purchase the attachment for only 250 rubles + 200 rubles. for the whetstone.

Making a sharpening machine with your own hands step 1

I installed an electrical box on the engine, placed a capacitor in it to start the engine, a toggle switch - a switch and a power supply for the lamp.

I used a toggle switch from a Soviet tube TV - it turns out to be a reliable thing; first I installed a modern, beautiful Chinese toggle switch - when using it, the machine “stuttered” (worked with some jerks), and replacing the toggle switch with another of the same brand did not help until I installed a Soviet toggle switch.

Out of curiosity, I later installed these Chinese toggle switches on another engine, which also began to “stutter”, it’s a shame, I paid 100 rubles for 2 toggle switches. - I just threw money away...

Well, with the capacitor - everything is standard, I won’t describe 101 times how to connect three phase motor to 220V - it’s easy to find on Google, or in our article on.

Backlight for sharpening machine step 2

Also check out these articles

For illumination I used an unnecessary LED table lamp from IKEA, bought for home, but was not useful anywhere, the lamp is powered from the mains through an adapter, which I ripped out and hid its board in a box on the motor.

Tool rest for lathe step 3

To attach the tool rest, I used a furniture corner sharpened at the desired angle, then I attached a piece of 32x32 corner to it, in which I sawed a groove and installed a tool rest on it from a piece of 4 mm steel. The tool rest is fastened with a countersunk screw; thanks to the groove in the corner under the tool rest, the tool rest can be moved closer or further from the grindstone. The corner is also attached to the casing with a screw, which allows you to adjust the angle of the tool rest relative to the whetstone.

From a furniture hanger I made a corner for attaching protective glass; for this I used a piece of plexiglass 6 mm thick.

The sharpening stone I used was 200x20 mm gray - I like these ones better for their hardness, the white ones crumble a lot. I know about marking stones, but I don’t do professional steel processing to spend a long time selecting a stone according to its parameters.

When installing the stone, I placed two cardboard washers, as required, so that when tightening the nuts, the whetstone would not burst.

About the safety of a homemade sharpening machine

We read the theory - we know...

The casing of my emery machine is not closed on one side - for safety reasons this is not possible, the casing should cover the stone as much as possible, but I decided for myself that sometimes it is convenient for me to sharpen something on the side of the stone, although this is not recommended. And in general, I usually finish my machines gradually, I think in the future, when I want, I will still make a cover for the casing so that it covers the sharpening stone on all sides.

But my machine also has safety advantages:

- the protective glass on Chinese machines is much thinner than I used;

- The machine speed is 1380 rpm, although the whetstone is designed for 3000 rpm. per minute This means my stone will have a very small chance of breaking.

What did I get

- I received an excellent homemade machine for sharpening drills, knives and other tools, the machine has enough power even for sharpening axes - tested;

- The machine speed is low, the sandpaper sharpens better at 3000 revolutions, but mine works quietly and persistently, I would say :)

Recommendation for choosing a motor for a homemade grinding machine

The engine is taken depending on your needs, if you are going to sharpen only awls, small knives, etc., then an engine from washing machine from the USSR. Such engines usually have 1380 rpm. per minute and 180-250 watts of power. Now there are engines from modern automatic washing machines, but they are more difficult to connect - you need a special board, but you can regulate the speed on them.

For more confident work, it is better to take a 400W engine and 1380-3000 rpm. Such a sharpener will be a good help in the workshop.

But if you want to work with large parts, sharpen crowbars, for example :), then you need to use a motor of about 750 W or more and 3000 rpm.

Photo of self-made emery:

Greetings, Samodelkins!

Today I want to show you how you can use the materials that are (or at least should be) in almost every workshop to make an excellent device for sharpening knives evenly.

Initially, the master wanted to buy a ready-made device for sharpening knives in China (namely in the Aliexpress online store), but he thought why not try to make such a sharpener himself. Moreover, the prices for this product from Chinese friends are rather high.

For self-production you will need the following materials and tools:

1. Ordinary board;

2. Sandpaper;

3. Screwdriver;

4. Hammer;

5. Thick electrode 1 pc;

6. Jigsaw;

7. A piece of laminate;

8. Bolts and nuts;

9. Wooden handle;

10. Hex key;

11. Fluoroplastic or textolite (fiberglass).

Let's get down to actually making the sharpener.

First, let's take an ordinary board and cut a piece out of it. Then you need to process the resulting wooden blank, namely sand it with sandpaper.

It will serve as the base for our homemade sharpening device.

In terms of size, we get it to be 26 cm in length, the width of the workpiece is 6.5 cm, and the height of the wooden base is 2 cm.

You also need to make holes in this board. In total, this part of the future product will have 6 through holes. We drill 2 holes for the stand itself (more on that a little later). Nearby we drill another hole of a smaller diameter, and also on the other side of the board we drill 3 more holes that will serve to attach the pressure plate.

Insert nuts into the holes made.

In the future, these nuts can be placed on glue so that they do not fall out, but for now everything seems to be quite tight.

Then we will start making the guide post itself. The master made it from an ordinary thick electrode. It needs to be bent in half. Next, using a hammer, the author knocked off the entire upper part of the welding electrode and ground it. By the way, you can also grind using an ordinary screwdriver. To do this, simply insert the electrode into the screwdriver chuck and, holding sandpaper in your hand, grind the product.

On at this stage We insert the resulting workpiece (guide post) from the electrode into these two holes.

We insert it not at a right angle, but at a slight angle. The guide angle is somewhere between 65 and 70 degrees.

Everything fits quite tightly, but also for greater reliability of our design, in the future it will be possible to attach the guide post with epoxy glue, or with some other glue, or with something else.

But perhaps the master is mistaken and this is not fluoroplastic. Fluoroplastic is most often white and somewhat slippery. Most likely it is textolite or fiberglass. But in essence it’s not that important. The main thing is that this material is quite hard and does not wear off.

From this piece (fluoroplastic or non-fluoroplastic), the author cut out a kind of pressure plate. He made holes in it, as well as small recesses, so that the caps would extend slightly into the depths of the plate.

Then we place this plate on the previously made wooden base. Secure with screws.

The author took the screws with a hex key. The master also made a small hole in the base of the future knife sharpener so that this key would always be in this sharpener.

The whole thing is clamped and they (the screws) are actually not visible on the plate.

But here, the master did not do the countersunk work, since the sharpening part of the tool will not touch this screw.

Next, the author made such a plate from the same fluoroplastic.

In this plate I made 2 holes for the same hexagonal screw.

Next, the whole thing is placed here and pressed with the help of a lamb.

Then the master made just such a guide for the sharpening stones.

The length of the guide is 57 cm. The author made it from an ordinary steel rod. Also cleaned it up. And on one of the ends I put this handle (it looks like it came from an old Soviet file).

You can also strengthen this connection by planting wooden handle from the file to the glue, but it fits in here quite tightly, nothing falls out.

Regarding the attachment of the sharpening stones themselves. The author took a small piece of the clamp, cut it and made holes. As a result, we got corners like this, two identical ones.

And here I put a nut with a thread and a clamping screw.

The master also installed a spring on the guide so that sharpening stones could be changed without unscrewing the nut with the clamping screw.

The author made the sharpening stones themselves, or rather the base for these stones, from an ordinary piece of laminate. Just cutting it into strips.

The width of the strips is 2.5 cm, and the length is about 20 cm.

The pieces of laminate already have ready-made grooves, which is where the corners of the guide part of the device will go.

Then the author glued sandpaper to the laminate pieces using double-sided tape and labeled which one went where. And, in fact, this is how it all turned out:

This whole thing is quite easy to set up. Using the groove of the laminate we get into one corner of the guide, and with the help of a spring we press the sharpening stone with the second corner.

All. Nothing falls out anywhere. Everything lies flat and quite tightly.

Let's continue assembling our device. We insert the guide with the sharpening stone attached to it into the hole prepared in advance for it, and you can safely begin the process of sharpening the knife.

The stroke is quite large due to the fact that here the author removed a small chamfer on both sides.