Many craftsmen often think about assembling a homemade CNC machine. It has a number of advantages and will allow you to solve a large number of tasks more efficiently and quickly.

They carry out milling and cutting of almost all materials. In this regard, the temptation to manufacture such a device is quite great. Maybe it's time to take matters into your own hands and replenish your workshop with new equipment?

Numerically controlled machines have become widespread not only in industrial production, but also in private workshops. They allow flat and profile processing of metal, plastic and wood.

In addition, you cannot do without them when performing engraving and drilling and filler work.

Almost any problem solved using similar devices, is performed at a high level.

If you need to draw something on a board or a wooden slab, you just need to create a layout in a computer program and transfer it to the product using CNC Milling. In most cases, it is simply impossible to perform such an operation manually, especially if we're talking about about high accuracy.

All professional equipment of this type is characterized high level automation and ease of operation. Only basic skills in working with specialized computer programs are required to solve simple material processing problems.

At the same time, even with CNC they cope with their goals. With proper configuration and the use of high-quality components, you can achieve good accuracy, minimal backlash and acceptable operating speed from the device.

DIY CNC machine

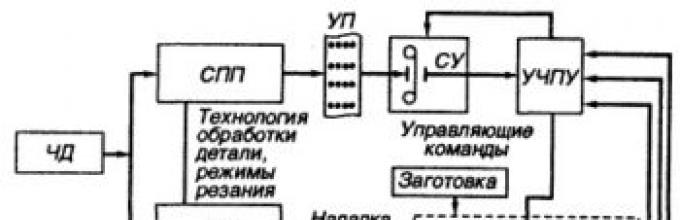

Functional diagram of a CNC machine.

So, how to make this device? To make a CNC machine with your own hands, you need to spend time developing the project, as well as familiarize yourself with existing factory models. Following these first and most simple rules, you will be able to avoid the most common mistakes.

It is worth noting that a CNC milling machine is a technically complex device with electronic elements. Because of this, many people believe that it cannot be done by hand.

Of course, this opinion is wrong. However, it must be borne in mind that for assembly you will need not only a drawing, but also a certain set of tools and parts. For example, you will need a stepper motor, which can be taken from a printer, etc.

The need for certain financial and time costs should also be taken into account. If such problems are not terrible, then produce an affordable and effective unit with coordinate positioning cutting tool for processing metal or wood is not difficult.

Scheme

The most difficult stage of CNC machining on metal and wood is choosing the optimal equipment layout. Everything here is determined by the size of the workpiece and the degree of its processing.

For domestic purposes, it is better to give preference to a drawing of a small device with the necessary set of functions.

One option could be a design consisting of two carriages that will move in a plane. Steel grinding rods work well as a base. Carriages are attached to them.

You will also need a motor and screws with rolling bearings to ensure the transmission. The CNC router will be controlled using a program.

Preparation

To automate a homemade CNC milling machine, you need to think through the electronic part as much as possible.

Drawing of a homemade machine.

It can be divided into several elements:

- power supply that supplies power to the motor and controller;

- controller;

- driver that regulates the operation of moving parts of the structure.

Then, to build the machine yourself, you need to select assembly parts. It is best to use available materials. This will help minimize the cost of the tools you need.

The base is usually made of wood, plexiglass or metal. It is important that no vibrations occur during the movement of the calipers. They will lead to inaccurate operation of the device. In this regard, it is necessary to correctly develop their design.

Here are some tips for choosing parts:

- rods with a diameter of up to 12 mm are suitable as guides;

- the best option for a caliper would be textolite;

- SD is usually taken from printers;

- The cutter fixation block is also made of textolite.

Assembly instructions

After preparing and selecting the parts, you can begin assembling the milling unit for processing wood and metal.

First of all, you should check all the components again and make sure that their sizes are correct.

CNC device diagram.

The assembly sequence looks approximately as follows:

- installation of caliper guides, their fastening to the side surfaces of the structure;

- grinding in the calipers as a result of their movement until a smooth ride can be achieved;

- bolt tightening;

- installing components on the device base;

- securing lead screws with couplings;

- fastening to the screws of stepper motor couplings.

All electronic components should be located in a separate unit. Thus, the likelihood of failure during operation will be minimized. This type of placement of electronics can be called the best design.

Features of work

Once the CNC machine has been assembled with your own hands, you can begin testing.

The actions of the machine will be controlled by software. It must be chosen correctly. First of all, it is important that the program is working. Secondly, it must maximize all the capabilities of the equipment.

Kinematic diagram of the device operation.

The software must contain all the necessary drivers for the controllers.

You should start with simple programs. During the first starts, it is necessary to monitor each pass of the cutter to ensure that the cutting width and depth are correct. It is especially important to control the three-dimensional versions of such devices.

Bottom line

CNC woodworking devices incorporate various electronics into their design. Because of this, at first glance, it may seem that such equipment is very difficult to make on your own.

In fact, do-it-yourself CNC is a feasible task for everyone. You just need to believe in yourself and your abilities, and then you can become the owner of a reliable and efficient milling machine that will become the pride of any master.

For many home craftsmen, it may seem that this is somewhere on the verge of fantasy, since this equipment is a structurally, technically and electronically complex device.

Meanwhile, having the corresponding drawings at hand, the entire required material and a tool, a mini homemade wood milling machine, equipped with CNC, you can make with your own hands.

Of course, for this you will have to spend some effort, including financial, but nothing is impossible, and if you approach this issue correctly and competently, anyone can make a homemade desktop mini wood milling machine with a CNC block with their own hands House master.

As you know, such a mini woodworking unit is distinguished by the accuracy of the processing, ease of control of all work processes, as well as the high quality of the finished product.

Currently, there are several ways to implement a homemade desktop CNC milling machine in a mini version for working on wood and other materials.

First of all, you can purchase a special kit for assembling this type of structure, or you can carry out all the necessary work yourself, resulting in a finished product with high quality processing.

If the decision is made necessary work When designing and assembling a mini table-top milling machine for working on wood and other materials with CNC by yourself, with your own hands, you should start by choosing the most optimal layout of the future unit.

In this case, you can take a small old drilling machine as the initial equipment and replace the working body in the form of a drill directly with a cutter.

You should definitely think carefully about how the mechanism responsible for the necessary movement in three independent planes will be arranged.

You can try to assemble such a mechanism from recycled carriages from an old printer, which will make it possible to ensure the movement of the working cutter in two planes.

Here you can simply connect the necessary software, which will make your homemade desktop CNC milling machine automatic, but this design can only work on wood, plastic or thin metal.

In order for a homemade milling machine, assembled with your own hands, to be able to perform more serious operations, it must be equipped with a stepper motor with high power ratings.

This type of motor can be obtained from a standard version of the electric motor through minor modifications. This will completely eliminate the use of a screw drive, while all its advantages will be preserved in full.

The required force on the shaft in a homemade unit is best transmitted through timing belts.

If, to ensure the necessary movement of the working cutter in a homemade CNC milling machine, it is decided to use homemade carriages from printers, then it is better for these purposes to take these devices from large printer models.

When creating a CNC milling unit with your own hands, special attention should be paid to the manufacture of the milling mechanism, which will require the appropriate drawings.

Milling machine assembly

It is best to take a rectangular beam as the basis for a homemade milling machine, which should be firmly secured to the guides.

The entire structure must have high rigidity, and it is better if welding work is kept to a minimum.

The fact is that in any case, welding seams are subject to destruction and deformation under certain loads; when the machine is operating, its frame will be subject, among other things, to vibration, which can negatively affect these fastening elements, which, in turn, will lead to to a settings failure.

To enhance rigidity, it is recommended to fasten the beam and fastening elements using screws of certain diameters.

This should completely eliminate possible play during operation of a CNC milling machine, as well as deflection of the guides under heavy loads.

Using exactly the same principle, a homemade milling and engraving machine equipped with CNC is assembled with your own hands. The process of assembling with your own hands is enough to use a functional CNC milling machine, which is described in detail in the video below.

The design of the unit requires mandatory provide for lifting the working tool in a vertical position, for which it is recommended to use a screw drive.

In turn, for the necessary rotation output, a toothed belt should be used directly on the lead screw.

The vertical axis, which is also a mandatory element of any CNC milling machine, is made from an aluminum plate.

It should be precisely adjusted to the dimensions that were obtained at the design stage of the unit and included in the corresponding drawings.

At home, you can cast the vertical axis using a muffle plate, in which case you should use aluminum.

After this, two stepper-type motors should be mounted directly on the housing immediately behind the axis, one of which will be responsible for horizontal movement, and the second, respectively, for vertical movement.

All rotation must be transmitted through the belts. After all the elements are in place, the homemade milling machine should be checked in operation with manual control, and if any shortcomings are identified, they should be eliminated on the spot.

A little about stepper motors

Any CNC machine, including an engraving machine, must be equipped with stepper-type electric motors.

When assembling homemade CNC milling equipment, motors from old dot matrix printers can be used as such a motor. Most dot matrix printers have two of these elements with sufficient power.

In addition, dot matrix printers also have steel rods made of durable steel, which can also be used in a homemade machine.

In this case, it should be noted that to assemble such a unit with your own hands, you will need three separate stepper motors, which means you will have to look for and disassemble two dot matrix printers.

It is better if such motors have about five separate control wires, since in this case the functionality of the homemade machine will increase several times.

When selecting stepper motors for a homemade CNC milling machine, you need to find out the number of their degrees per step, as well as the operating voltage and winding resistance.

This will help you subsequently configure all the equipment software correctly.

It is best to secure the stepper motor shaft using a rubber cable with a thick winding. It will also help when attaching the engine itself directly to the stud.

You can make the clamps from a self-made bushing with a screw. To do this, take nylon, and as a tool, a drill and a file.

How to make an engraving and milling machine with a CNC unit with your own hands is described in detail in the video below.

Electronic support

The main element of any CNC machine is its software.

In this case, you can use a homemade one, which will include all the necessary drivers for the installed controllers, as well as stepper motors, and in addition, standard power supplies.

An LPT port is required. It will also be necessary to think about a work program that will provide not only control, but also management of all necessary operating modes.

The CNC unit itself should be connected directly to the milling unit through the above port, always through the installed motors.

When selecting the necessary software for a homemade machine, you need to rely on one that has already proven its stable operation and has huge functionality.

Video:

It should be remembered that electronics will mainly influence the accuracy and quality of all operations performed on CNC equipment.

After all the necessary electronics are installed, you need to download all the programs and drivers necessary for the operation of the desktop milling machine.

Next, immediately before the machine begins to be used for its intended purpose, the electronic software should be checked in operation and, if necessary, all identified deficiencies should be corrected on site.

All of the above-described operations for assembling a CNC milling machine with your own hands are also suitable for creating a homemade jig boring unit, as well as many other equipment of this class.

In any case, if all the work of assembling a CNC-equipped milling unit with your own hands is done correctly and in accordance with technology, you will home handyman It will be possible to perform many complex operations, both on metal and wood.

How to make your own milling machine with a CNC block is described in detail in the video in our article.

For most home craftsmen, making a unit such as a CNC milling machine with your own hands is something on the level of a fantastic plot, because such machines and mechanisms are devices that are complex in design, constructive and electronic understanding.

However, having at hand necessary documentation, as well as the required materials, devices, mini-milling homemade apparatus, equipped with CNC, it is quite possible to do it yourself.

This mechanism is distinguished by the accuracy of the processing performed, ease of control of mechanical and technological processes, as well as excellent performance and product quality.

Principle of operation

Innovative machines for milling with blocks on computer control intended for making complex designs on semi-finished products. The design must have an electronic component. Taken together, this will allow for maximum automation of work processes.

To model milling mechanisms, you first need to become familiar with the fundamental elements. The actuating element is a milling cutter, which is mounted in a spindle located on the shaft of an electric motor. This part is fixed to the base. It is capable of moving in two coordinate axes: X and Y. To fix the workpieces, design and install a support table.

The electric adjustment unit is connected to the electric propulsion motors. They will ensure movement of the carriage relative to the workpieces or semi-finished products being processed. Using a similar technology, 3D graphic images are produced on wooden planes.

The sequence of work performed using this CNC mechanism:

- Writing work program, due to which the movements of the working body will be performed. For this procedure, it is best to use specialized electronic complexes designed to perform adaptation in “makeshift” copies.

- Mounting semi-finished products on a table.

- Output of software to CNC.

- Starting mechanisms, monitoring the passage of automatic equipment manipulations.

To obtain the maximum level of automation in 3D mode, correctly assemble the diagram and designate certain components. Experts strongly advise initially studying production copies before starting to build a milling machine with your own hands.

Scheme and drawing

Diagram of a CNC milling machine

The most critical phase in the manufacture of a homemade analogue is the search for the optimal process for manufacturing the equipment. It directly depends on the dimensional characteristics of the workpieces being processed and the need to achieve a certain quality in processing.

To obtain all the necessary functions of the equipment, the best option is to make a mini-milling machine with your own hands. Thus, you will be confident not only in the assembly and its quality, but also in its technological properties, and you will know in advance how to maintain it.

Transmission components

The most successful option is to design 2 carriages that move along perpendicular axes X and Y. It is better to use polished metal rods as a frame. Mobile mobile carriages are “dressed” on them. To correctly manufacture the transmission, prepare stepper motors, as well as a set of screws.

For improved automation of work processes of CNC milling machines designed by yourself, it is necessary to immediately complete the electronic component down to the smallest detail. It is divided into the following components:

- used to conduct electrical energy to stepper motors and supplies power to the controller chip. The running modification is considered to be 12V 3A;

- its purpose is to send commands to the engines. For correct execution all specified operations of a CNC milling machine, it will be enough to use a simple circuit to monitor the performance of 3 motors;

- drivers (software). It also represents an element for adjusting the moving mechanism.

Video: DIY CNC milling machine.

Components for a homemade milling machine

The next and most important step in building milling equipment is the selection of components for building a homemade unit. The best way out of this situation is to use available parts and devices. It is possible to take hard wood (beech, hornbeam), aluminum/steel or organic glass as the basis for desktop 3D machines.

For normal operation of the complex as a whole, it is necessary to develop the design of the calipers. At the moment of their movement, vibrations are not unacceptable; this will cause incorrect milling. Therefore, before assembly, components are checked for operational reliability.

Practical advice by choosing the components of a CNC milling machine:

- guides - well-polished steel rods Ø12 mm are used. The length of the X axis is about 200 mm, Y - 100 mm;

- caliper mechanism, optimal material– textolite. Standard platform dimensions are 30×100×50 mm;

- stepper motors - engineering experts advise using samples from a 24V, 5A printing device. They have quite significant power;

- a block for fixing the working element; it can also be built using textolite. The configuration directly depends on the existing tool available.

The procedure for constructing CNC milling equipment

After completing the selection of all the necessary components, you can completely freely build an oversized milling mechanism equipped with CNC with your own hands. Before proceeding with the actual design, we check the components again, their parameters and workmanship are monitored. This will further help avoid premature failure of the mechanism chain.

For reliable fixation of equipment components, specialized fastening parts are used. Their design and execution directly depend on the future design.

Scroll necessary actions to assemble small CNC equipment to perform the milling process:

- Mounting the guide axes of the support element, fixing them on the extreme parts of the machine.

- Grinding in calipers. It is required to move along the guides until smooth movement is achieved.

- Tightening the screws to secure the caliper device.

- Fastening components to the base of the working mechanism.

- Mounting lead screws and couplings.

- Installation of main engines. They are attached to the coupling bolts.

Electronic components are located in a self-contained cabinet. This ensures minimization of malfunctions during technological operations with a milling cutter. The plane for mounting the working machine must be without differences, because the design does not provide for level adjustment screws.

After completing the above, proceed to perform mock tests. First you need to install a lightweight program to perform milling. During the work process, it is necessary to continuously check all passages of the working tool (cutter). Parameters that are subject to constant monitoring: depth and width of processing. This especially applies to 3D processing.

Thus, referring to the information written above, making milling equipment with your own hands provides a whole list of advantages over conventional purchased analogues. Firstly, this design will be suitable for the expected volumes and types of work, secondly, maintainability is ensured, since it is built from scrap materials and devices, and thirdly, this equipment option is inexpensive.

Having experience in designing such equipment, further repairs will not take much time, downtime will be reduced to a minimum. Such equipment may be useful to your neighbors summer cottage to perform your own repair work. By renting out such equipment, you will help your close friend in his work, and count on his help in the future.

Having understood the design and functional features of milling machines, as well as the load that will fall on it, you can safely begin its manufacture, relying on the practical information provided throughout the text. Design and complete assigned tasks without any problems.

Video: homemade CNC wood milling machine.

Nowadays, handicraft people can increasingly find new machines that are controlled not by hands, as we are all used to, but by computer software and computerized equipment. This innovation is called CNC (computer numerical control).

This technology is used in many institutions, large industries, as well as in private workshops. An automated control system allows you to save a lot of time and also improve the quality of the products produced.

The automated system is controlled by a computer program. This system includes asynchronous motors with vector control, having three axes of movement of the electric engraver: X, Z, Y. Below we will look at what machines with automatic control and calculations.

As a rule, all CNC machines use an electric engraver or milling cutter, on which you can change attachments. A numerically controlled machine is used to add decorative elements to certain materials and more. CNC machines, due to advances in the computer world, must have many functions. These functions include:

Milling

A mechanical process of processing a material, during which a cutting element (an attachment in the form of a milling cutter) produces rotational movements on the surface of the workpiece.

Engraving

It consists of applying one or another image to the surface of the workpiece. To do this, use either cutters or a graver (a steel rod with one end pointed at an angle).

Drilling

Mechanical processing of material by cutting, using a drill, which creates holes different diameters and holes having many faces of different sections and depths.

Laser cutting

A method of cutting and cutting material in which there is no mechanical impact, high accuracy of the workpiece is maintained, and deformations made by this method have minimal deformations.

Plotter

High-precision drawing of complex diagrams, drawings, and geographical maps is carried out. Drawing is done using a writing block, using a specialized pen.

PCB drawing and drilling

Manufacturing of circuit boards, as well as drawing electrically conductive circuits on the surface of a dielectric plate. Also drilling small holes for radio components.

What functions your future computer-controlled machine will perform is up to you to decide. Next, let’s look at the design of a CNC machine.

Type of CNC machines

The technological features and capabilities of these machines are equivalent to universal machines. However, in modern world, there are three types of CNC machines:

Turning

The purpose of such machines is to create parts based on the type of bodies of rotation, which consists of processing the surface of the workpiece. Also production of internal and external threads.

Milling

The automated operation of these machines consists of processing the planes and spaces of various body blanks. They carry out flat, contour and stepped milling, at various angles, as well as from several sides. They drill holes, cut threads, ream and boring workpieces.

Drilling - boring

They perform reaming, hole drilling, boring and reaming, countersinking, milling, threading and much more.

As we can see, CNC machines have a wide range of functionality that they perform. Therefore, they are equated to universal machines. All of them are very expensive and it is simply impossible to buy any of the above installations due to financial insufficiency. And you might think that you will have to perform all these actions manually throughout your life.

You don't have to be upset. The skillful hands of the country, from the first appearance of factory CNC machines, began to create home-made prototypes that work no worse than professional ones.

All components for CNC machines can be ordered on the Internet, where they are freely available and are quite inexpensive. By the way, you can make the body of an automated machine yourself, and you can go to the Internet for the correct dimensions.

Tip: Before choosing a CNC machine, decide what material you will be processing. This choice will be of major importance when constructing the machine, since it directly depends on the size of the equipment, as well as its costs.

The design of the CNC machine depends entirely on your choice. You can purchase a ready-made standard set of all the necessary parts and simply assemble it in your garage or workshop. Or order all equipment separately.

Consider a standard set of parts on the picture:

- Directly Workspace, which is made from plywood, is a table top and a side frame.

- Guide elements.

- Guide holders.

- Linear bearings and sliding bushings.

- Support bearings.

- Lead screws.

- Stepper motor controller.

- Controller power supply.

- Electric engraver or router.

- A coupling connecting the lead screw shaft to the shaft of stepper motors.

- Stepper motors.

- Running nut.

Using this list of parts, you can safely create your own CNC wood milling machine with automated operation. Once you have assembled the entire structure, you can safely begin work.

Principle of operation

Perhaps the most important element on this machine is the milling cutter, engraver or spindle. It depends on your choice. If you have a spindle, then the tail of the cutter, which has a collet for fastening, will be tightly attached to the collet chuck.

The chuck itself is directly mounted on the spindle shaft. The cutting part of the cutter is selected based on the selected material. An electric motor, which is located on a moving carriage, rotates the spindle with a cutter, which allows processing the surface of the material. Stepper motors are controlled by a controller, to which commands are sent from a computer program.

Electronics The machine works directly on the provision of computer software, which must be supplied with the ordered electronics. The program transmits commands in the form of G codes to the controller. Thus, these codes are stored in random access memory controller.

After selecting a processing program on the machine (finishing, roughing, three-dimensional), commands are distributed to stepper motors, after which the surface of the material is processed.

Advice: Before starting work, you need to test the machine, specialized program and run a test part to make sure the CNC is working correctly.

Assembly

Machine assembly with your own hands It won't take you too much time. Moreover, on the Internet now you can download a lot of different schemes and drawings. If you bought a set of parts for a homemade machine, then its assembly will be very quick.

So, let's look at one of them drawings the actual hand machine.

Drawing of a homemade CNC machine.

As a rule, the first step is to make a frame from plywood, 10-11 millimeters thick. The tabletop, side walls and movable portal for installing a router or spindle are made only from plywood material. The tabletop is made movable, furniture guides of appropriate sizes are used.

The end result should be a frame like this. After frame construction ready, a drill and special bits come into play, with which you can make holes in the plywood.

Frame of the future CNC machine.

In the finished frame, it is necessary to prepare all the holes in order to install bearings and guide bolts in them. After this installation, you can install all fasteners, electrical installations etc.

After the assembly is completed, important stage becomes the setting of the machine software and computer program. When setting up the program, the operation of the machine is checked for the correctness of the specified dimensions. If everything is ready, you can begin the long-awaited work.

Tip: Before starting work, you need to check the correct fastening of the workpiece material and the reliability of fastening the working attachment. Also make sure that the selected material matches the machine being manufactured.

Equipment setup

The CNC machine is set up directly from the working computer on which the program for working with the machine is installed. It is into the program that the necessary drawings, graphs, and drawings are loaded. Which are converted in sequence by the program into G codes necessary to control the machine.

When everything is loaded, trial actions are performed regarding the selected material. It is during these actions that all necessary preset sizes are checked.

Advice: Only after a thorough check of the machine’s functionality can you begin full-fledged work.

Safety precautions

The rules and safety precautions when working with this machine are no different from working on all other machines. Below are the most important ones:

- Before work, check that the machine is in good working order.

- Clothes must be tucked in properly so that nothing sticks out anywhere and cannot get into the working area of the machine.

- You must wear a hat that will hold your hair in place.

- Near the machine there should be a rubber mat or low wooden sheathing, which will protect against electrical leakage.

- Access to the machine by children must be strictly prohibited.

- Check everything before operating the machine fasteners on their strength.

Advice: You must approach working on the machine with a clear head and understanding that if you do it incorrectly, you can cause irreparable harm to yourself.

You can find complete safety requirements when working with the machine on the World Wide Web, i.e. on the Internet and check them out.

Video reviews

Review of homemade CNC machine assembly

Video review simple machine CNC

Overview of the capabilities of a homemade CNC machine

Stepper Motors Overview

Review video multi-channel driver for stepper motors

Currently, you can purchase ready-made machines to equip your own workshop, but all this will be quite expensive. Homemade machines will help the master in his practical work , and will not burden his budget. Why buy something that you can do yourself, and even in relation to specific conditions.

Each owner chooses the equipment of his own workshop himself. It depends on the hobby, i.e. type of work and area of the premises. Minimum area of a home workshop in which it makes sense to place equipment is 3-4 m².

It can be located in a small room or on the balcony of an apartment, a separate building on its own site or in a garage. Perfect option- This is a secluded room in which you can make noise without disturbing other people.

According to its purpose, a home workshop can be universal, i.e. to carry out any work that unexpectedly arises in everyday life, or have a specific direction, associated with the master’s hobby. Most often, workshops are equipped for working with wood, i.e. For carpentry work. Quite often there is a need for metal processing ( locksmith work) And car repair.

In general, setting up a home workshop includes the following elements:

- structures for storing tools and materials (racks, shelves, cabinets);

- equipment for work (workbenches, work tables);

- machines for processing materials;

- devices for mechanizing work, facilitating labor, preparing tools, etc.

The equipment must be placed so that there is access to it free approach, was observed safety and fire regulations, provided minimal comfort.

Shelves for tools and materials

Setting up your home workshop begins from installing practical shelves for a DIY tool. They can be made of metal or wood, and also have a combined design - metal carcass with shelves made of wood, plywood, chipboard, plastic, etc.

The following stand out basic structures:

- Racks in the form of a frame and shelves located at different heights.

- Shelves mounted on the wall. They can be installed on brackets or attached with dowels directly to the wall surface.

- Hanging shelves with ceiling mounting.

Practical shelf-boards have this design. The basis is a shield cut from plywood 8-12 mm thick.

Practical shelf-boards have this design. The basis is a shield cut from plywood 8-12 mm thick.

There are 3 types of fasteners mounted on it:

- a rail with slots for placing tools with a handle in a vertical position (hammer, screwdrivers, chisels, etc.);

- shelves with a side for placing boxes with small tools (drills, taps, dies, etc.);

- hooks for hanging small tools (knife, scissors, measuring tool, etc.).

This shelf-shield is fixed to the wall using dowels.

Carpentry workbench

A carpentry workbench is durable table with a working surface on which they are fixed holdfast(2 pieces), clamps to secure the workpiece when planing with a plane, there are places for installation milling cutter and other manual machines.

Important. The dimensions of the workbench are selected based on practical considerations.

The height should ensure ease of work, taking into account the actual height of the master. The length should be at least 1 m (usually 1.7-2 m), and width - 70-80 cm.

Instructions for making a carpentry workbench:

- The working surface is made in the form of a shield with tightly fitted boards with a thickness of at least 55 mm. Beech, oak, and hornbeam are best suited. They should first be soaked in drying oil. Strengthening is achieved with a beam measuring 4-5 cm, which is attached along the entire perimeter of the shield.

- Vertical table supports can be made of pine or linden. Typically, a beam measuring 12x12 or 15x15 cm with a length of about 120-135 cm is used. The supporting elements are connected by horizontal jumpers made of a wide board, fixed at a height of 20-30 cm from the floor.

- Tools and accessories are stored on shelves that are located under the lid. It is better to make them in the form of a cabinet with a door. Shelf panels can be placed on the wall above the workbench.

- On work surface attach a pair of homemade or factory-made carpentry vices.

Reference. The workbench can be mobile (movable), folding (collapsible) or stationary. In the latter case, it is recommended to bury the supports into the ground by 15-20 cm.

Vise

For a homemade vice you will need a long screw rod with a diameter of at least 20 mm with a threaded part length of at least 14-16 cm, metal studs and wooden blocks.

For a homemade vice you will need a long screw rod with a diameter of at least 20 mm with a threaded part length of at least 14-16 cm, metal studs and wooden blocks.

Manufacturing is carried out in the following order:

- Cut out wooden block(can be made of pine) about 20x30 cm in size and at least 5 cm thick, in which a hole for a screw is drilled in the center, and at the bottom there are 2 holes for guide pins. This first vise jaw is permanently fixed to the work surface.

- The second sponge is cut from a similar board and has dimensions of 20x18 cm. This will be a movable element.

- A screw pin is passed through the jaws. To prevent displacement of elements, studs with a diameter of about 8-10 mm are fixed. A handle is installed on the screw rod.

How to make a metal workbench with your own hands?

To carry out plumbing work you will need a metal workbench. Its standard size: length 1.8-2.1 m, width – 0.7-0.8 m, height – 0.9-1.2 m. Manufacturing includes the following steps:

- Assembling the workbench frame with imparting longitudinal rigidity.

- Assembling and securing 2 cabinets in the form of a frame covered with a metal sheet.

- Installation of the working surface - a wooden board covered with a metal sheet on top.

- Installation of a tool rack, which is attached to the back of the workbench and further strengthens it.

- rack beams – profile pipe with a wall of at least 2 mm, size 4x6 cm. Needed - 4 pcs.;

- beams measuring 5x4 cm for horizontal linking of posts, providing longitudinal rigidity. Quantity – 3 pcs.;

- profiled pipe (9 pcs) for making a frame for cabinets measuring about 4x3 cm with a wall thickness of at least 1 mm;

- a 5x5 cm corner for vertical rack posts with a height of 1.5-2 m. For horizontal linking, you can use a 4x4 cm corner;

- tabletop board with a thickness of at least 5 cm;

- a metal sheet for a working surface with a thickness of at least 6-8 mm.

Features of creating a wood lathe

A homemade lathe for working with wooden blanks includes the following elements:

- bed. It must have sufficient strength. It is better to make it from a metal profile (pipe, corner), but it can also be made from wooden beam. It is important to securely fasten the frame to the workshop floor and weight the structure at the bottom.

- Headstock or clamping spindle. As this element of the machine, you can use a head from a high-power drill.

- Tailstock. In order to ensure longitudinal feed of the workpiece, it is better to use a standard factory spindle with 3-4 cams.

- Support or stop for cutters. It must provide reliable fastening and the ability to move towards the workpiece, which is ensured by a screw rod.

- Tool table. A working surface should be formed on the bed on which cutters and other tools can be laid out.

- Drive unit. To create torque, an electric motor with a rotation speed of 1500 rpm and a power of 250-400 W is used. You can use the engine from washing machine. A belt drive is used as a transmission, for which pulleys of the required size are installed on the shafts.

Incisors

Even in homemade lathe better use factory cutters which will provide increased quality. However, if you wish, you can do this on your own. Homemade cutters wood can be made from the following materials:

- Steel reinforcement. The best option is a square section with a size close to the size of the factory tool.

- Files. A worn tool is selected, but without significant defects.

- car spring rectangular (square) section.

Prepared cutter blanks are sharpened. For roughing work, a semicircular cutting edge is used, and for finishing work, a cutter with a straight blade is needed. In addition, shaped and through cutters with specific sharpening may be required. Next, the cutting part requires hardening. To do this, it is heated and then lowered into engine oil.

Instructions for creating a stationary circular saw

The most important element of a stationary circular saw is reliable table with work surface. The most suitable for it is a metal sheet reinforced with stiffening ribs from a steel angle. The following parts are located on the worktop: cutting disc, guides, thrust and control elements.

Drive is provided electric motor power of about 0.8 kW with a minimum speed of 1700 rpm. Transmission – belt drive.

Drive is provided electric motor power of about 0.8 kW with a minimum speed of 1700 rpm. Transmission – belt drive.

Make circular saw Can from the grinder in the following order:

- Installation of the frame and production of the working surface. Cutting a space to install the disk.

- Fastening parallel stops from wooden beams.

- Installing a scale to adjust the cutting process.

- Installation of clamps for fixing guides and workpieces.

- Fastening the grinder from the bottom of the tabletop with the disk directed into the slot.

Assembling a homemade drilling machine

The procedure for assembling a homemade one drilling machine shown in the video below. It is based on an electric drill, which is mounted on a frame with the possibility of vertical movement.

Main elements of the machine:

- Electric drill.

- Metal base with clamps for workpieces (clamps).

- Stand for attaching a drill. It can be made from chipboard 2-2.5 cm thick. A good option- base from an old photographic enlarger.

- Feeding mechanism for cutting tools. Guide rails are installed on the stand to ensure strictly vertical movement of the drill. The easiest way to feed a tool is manual lever and springs. Adjustable stops are installed to control the depth.

CNC milling machines for wood and metal

When milling wooden parts software allows you to significantly expand the capabilities of the machine and the quality of processing. To form it, elements such as LPT port and CNC unit. To make a copy unit, you can use the carriages of an old dot matrix printer.

Assembling the wood router is carried out in the following order:

- The tabletop is made of chipboard or plywood with a thickness of at least 15 mm.

- A cutout is made for the cutter and its installation.

- The drive, transmission and spindle of the machine are secured.

- Stops and limiters are installed.

Assembling a metal router requires more solid foundation for the machine:

Assembling a metal router requires more solid foundation for the machine:

- Installation of a column and frame in the shape of the letter “P”. The elements are made from steel channel. In a U-shaped design, the bridge is formed by the base of the instrument itself.

- The guide elements are made from angle steel and are bolted to the column.

- The guide consoles are made of a rectangular pipe. A screw pin is inserted into them. The movement of the console is ensured using a car jack to a height of 12-15 cm.

- The worktop is made of chipboard or plywood.

- A vice, guides from a metal corner, and pin clamps are fixed on the tabletop.

- The rotating part is installed so that the shaft is vertical.

Thicknesser

A homemade thicknessing machine for wood includes the following elements:

- bed. It is made of 2 frames welded from a corner 40x40 or 50x50 mm. The frames are connected with studs.

- Broach. Rubber squeezing rollers from a washing machine work well. They are mounted on bearings and rotated manually using a handle.

- Working surface, table top. A wide board impregnated with drying oil is used, which is secured to the frame with bolts.

- Drive unit. You need a three-phase electric motor with a power of 5-6 kW with a rotation speed of at least 3000 rpm.

- casing. To protect the rotating parts, a casing of 4-5 mm thick steel sheet is installed, mounted on a frame made of steel angle 20x20 mm.

note

Can be used as a working body electric planer.

It is fixed with clamps on the working surface to form the required gap. This gap must be adjusted using shims and set taking into account the thickness of the workpiece.

Creating a wood sanding machine

Homemade grinding machine It has drum design, i.e. a rotating cylinder with a emery cloth. It can be produced in the following varieties:

- surface grinding type that provides grinding in only one plane;

- planetary a type capable of processing a part in different directions, creating an even plane on it;

- cylindrical grinding type for processing cylindrical workpieces.

When securing the abrasive cloth, the following recommendations should be taken into account:

- The width of the tape is about 20-25 cm.

- The strips are connected end-to-end, without a gap.

- To strengthen the joint seam, a thick tape is placed under it.

- Only high quality glue should be used.

- The shaft for the sanding strip has a side at the edges that protrudes by 2.5-4 mm.

- It is recommended to use thin rubber (for example, a bicycle inner tube) as a backing for the abrasive element.

Rules for operating a wood jointer

Homemade jointer will help with furniture and apartment repairs. When using it, the following rules should be observed:

- The jointer is adjusted in such a way that the maximum errors are ensured - vertically (perpendicular) - no more than 0.11 mm for every 1 cm; in plane - no more than 0.16 mm for every 1 m.

- When processing workpieces smaller than 3.5x35 cm, pushers should be used to hold them.

- Wear cutting element indicate scorch marks and mossiness on the surface of the part.

- An uneven surface after machining indicates an inaccurate positioning of the cutting edges.

Homemade garage gadgets

In a home workshop equipped in a garage, you can repair your car yourself. In particular, the following are of interest homemade devices and machines.

Hydraulic jack press

He will help when removing and crimping silent blocks car. With its help, a load of several hundred kg is provided.

He will help when removing and crimping silent blocks car. With its help, a load of several hundred kg is provided.

The structure consists of a frame and hydraulic jack. The frame is welded from a high-strength rectangular pipe.

After lifting the car, it becomes a stationary, reliable support for the car.

This allows you to safely press out the jammed part using internal clips from the bearing.

Ball joint remover

It can be made in different ways:

- Lever type. These are 2 levers connected in the center. On one side, a coupling bolt is installed on them. When acting on the support, it unscrews, bringing the ends of the levers closer together. In this case, one end is inserted between the support and the eye, the second - under the finger.

- Option "wedge". A wedge-shaped workpiece is cut from a metal plate. From the side of the upper corner, a strictly vertical cut is made at 70% of the height. This wedge is installed between the ball joint and the eye. Then it is hammered in until the finger comes out of the socket.