External tuning of a car is a kind of uniform, clothing by which both the car and its owner, naturally, are greeted. What details relate to external tuning? All kinds of body kits, trims, chrome parts, anti-wings (aka spoilers). All cars, without exception, even before production, pass through the hands and eyes of designers who create this or that appearance for them, but it often happens that the happy buyer and owner of the car remains dissatisfied with this design, and then... Then there is a need for improvement and external improvement your car, the search for possible solutions begins. One of these decisions becomes a strong desire to buy a spoiler. However, it is not at all necessary to buy it. If you read the following general information on how to do DIY spoiler, then it is quite possible that your obsession with buying a store copy will disappear.

Material and Tooling Options

There are several well-known ways to make a spoiler. Moreover, some craftsmen use tin blanks as a basis for the form, others use plaster castings, others cut them out of wood or foam plastic, and some, especially daring ones, can create a tuning masterpiece even from an ordinary newspaper. We will not take a specific example and dwell on it, because this is a matter of taste, skill, the size of your car and personal capabilities, but in any case you will need the following set of tools and materials:

- quite a large piece of fiberglass;

- reflective tape;

- two or three cans of paint;

- about the same number of cans of primer;

- approximately 3 kg of epoxy glue;

- five pieces of brushes for applying paint and glue;

- two rolls of sandpaper (coarse for shaping and fine for sanding).

By the way, get ready to work hard and painstakingly, because there is no way to complete such work in a day or two. Overall, expect to spend at least two weeks if you want a nice, neat spoiler.

The nuances of each material

- When working with iron, be careful and attentive to the edges of the cut pattern, because metal can seriously damage not only clothing, but also your own hands.

- When using foam plastic as a template, consider its hardness and density. To process it, either ordinary sandpaper, a file or even a sharp stationery knife can be used.

- The good thing about plaster molds is that, when poured, they take on almost any shape you have in mind. But do not forget that gypsum is a heavy and very fragile material. With one wrong move, it can not only split, but also turn into dust. In addition, you will still have to make some kind of form into which to pour it. It is better to use the same foam or wood.

- Well, the most masterpiece way is the newspaper method. To make a base for a spoiler from such an unusual material, you don’t need much intelligence. It is enough to unroll the sheet, roll it very tightly into a tight tube, securing it at the edges with glue so that it does not unwind, and then repeat these operations several times, laying newspaper tubes one after another, depending on the size of the designed spoiler.

In principle, this is not a complete list of all kinds of materials suitable for use and production of a spoiler. If the theory is clear to you, then the base can be made from anything - even from bread crumb, like criminals in prisons.

Final process

After making the base, you must make the so-called “reinforcement”. Simply put, taking a ready-made base, you need to give it the specific desired shape and wrap it in several (three or four) layers of fiberglass. Then the entire structure must be impregnated with epoxy glue, allowed to dry and harden, and a primer applied. After applying and drying the primer, the product is carefully (exactly carefully!!!) sanded with sandpaper so that the aerodynamics are ideal, and then it is painted and dried again. Finally, a reflective tape is glued to the aft part of the finished spoiler, although this is not necessary, and the spoiler is installed on the trunk lid, for example. Now your car will take on a sporty and fast look, and you will be greeted by the clothes... that you made yourself.

And just for fun:

Surely, one of the easiest ways to decorate an ordinary car externally, giving it the style of a racing car, is to make a spoiler. And it doesn’t matter that the automaker didn’t foresee this from the beginning. If you are good with your hands, then you can solve this problem yourself.

In this article you will not find thoughts on how to install a spoiler on a station wagon (for example, VAZ 2109), on a Gazelle, and especially on a truck. We will talk about the spoiler as a tuning element that will decorate any sedan. However, this information will also be useful for those who want to decorate any other car.

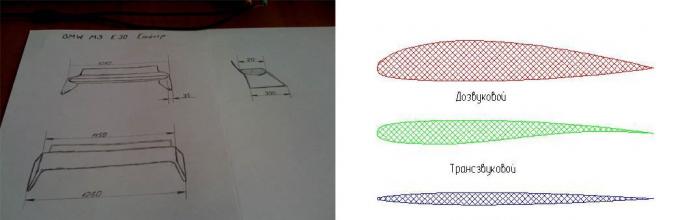

Of course, the main purpose of a spoiler is to improve the aerodynamics of the car. How is this achieved? An airplane wing, due to its design, generates lift.

The spoiler is a wing, as you can see in the photo. That is, it is designed so that the air flow presses the rear of the car to the ground. This is what improves aerodynamics.

In view of this, it is clear that a spoiler made without calculations is just an element of pretentious style. And if you make a spoiler without calculations, it can even spoil the aerodynamics.

Therefore, the first advice to those who want to make a spoiler with their own hands is to find a good engineer who can help with the design. The rest is a matter of technique.

How to make a regular spoiler with struts using ready-made calculations will be discussed below.

Frame preparation

So, at this stage we know the dimensions and design of the spoiler. The first thing we need to do is a metal frame. To do this you will need a sheet of galvanized iron. This material is well suited for its durability.

If you do not have experience and equipment in cutting and other metal work, it is better to contact an organization that has craftsmen and appropriate equipment.

The side spoiler struts should resemble the Latin letter L. If you decide to make a lip spoiler, then its design will be slightly different.

The thickness of galvanized metal for making the frame is 1.5 mm. The spoiler will be installed on the car using bolt mounts. The holes for the bolts in the spoiler struts are 6 mm.

Working with foam plastic

We can use foam plastic as a material for increasing volume. It may not have the required rigidity. However, its price is more than suitable for those who are not particularly interested in the aerodynamic properties of the spoiler. The weight of the foam is also good news. As a last resort, if you are seriously concerned about the choice of any material indicated in this article, it is better to address this question to a professional engineer.

So, we need to make shapes from polystyrene foam that we will use to cover the frame. We cut the foam with a utility knife with a large blade, using a building level for support. Another advantage of polystyrene foam as a material is its ease of processing. Using regular sandpaper we adjust the thickness and shape. However, do not get carried away, otherwise you will have to buy a new piece of material.

The foam pieces can be processed after they have been glued to the frame.

Video - cutting foam plastic.

Working with fiberglass

We buy polyester resin, glass mat and gelcoat, putty, primer, native color paint, varnish. Then:

- Apply a layer of gelcoat to the foam. It needs to be sanded and then covered with layers of polyester resin and glass mat.

- We cover the surface of the foam with fiberglass (or as some call it, glass carbonate). This must be done in two or more layers. The first layer will be made of glass mat with a density of 300, and the second - with a density of 600. We glue each next layer after the previous one has undergone the polymerization process. The final layer is again coated with polyester resin.

- Make sure that there are no air bubbles under the fiberglass layer when gluing. For greater reliability, you can walk over the surface of the glued layer with a notched roller.

Prices for 1 meter of glass mat 300 are about 100 rubles. Glass mat 600 - about 150 rub. for 1 p.m. Fiberglass can also be used to glue wing parts together.

If you want to save time on drying glued fiberglass, you can use a hair dryer.

Attention! At this stage, LEDs (or brake lights) are installed and wires are laid to power them (of course, if you planned to equip the spoiler with lighting devices).

To make the surface of the spoiler even and smooth, it can be puttied, sanded and primed, and finally painted and varnished. Be sure to check with the seller whether the materials you are purchasing are compatible with those you already use.

Gypsum matrix

If you want to make a copy of the finished spoiler, you can use plaster as a filling material. We place the spoiler in a polystyrene box and then fill it with liquid plaster. Once it has hardened, the mold for making the spoiler is ready. All that remains is to saw the cast in half and remove the original from which we removed the mold.

Cover the surface of the impression with cling film. You can also use a sheet of galvanized iron as a frame.

Pour plaster into the mold to create a new spoiler.

When the spoiler is ready, we put layers of fiberglass on it. All that remains is to putty, sand, prime, paint, and varnish.

These are just some of the ways to make a spoiler yourself. There are other options, such as a spoiler from a newspaper, as shown in the video below.

Many motorists believe that the highlight of a car is the spoiler.

Thanks to it, the car looks stylish and original, since it correlates with the exterior of the car, determining its appearance, and related to the design. This is its aesthetic function. A synonym for a spoiler is a rear wing. It looks like a football goal.

In general, this is an additional element for a car that performs a number of positive functions. Firstly, it improves the dynamic properties of the car, radically changing its appearance.

It is also necessary to increase the stability of the car and achieve optimal control, while simultaneously being a certain load for the front and rear of the body. Secondly, the spoiler changes the characteristics and movement of the air flow.

These are its main features that make it so popular. The presence of a spoiler on a car indicates that the car corners more confidently, eliminating the possibility of damage during a skid, increasing braking efficiency. It also prevents water and various types of dirt from getting on the car windows.

It is quite capable of completing the tasks assigned to it when the car speed reaches 80-90 km/h. The spoiler is mounted either on the rear door or on the trunk. True, there are other options.

1. Types of spoilers

Spoilers come in different types. They are created with their own hands, however, in most cases they are manufactured in a factory. Then this is mass production, which concerns a specific car model. The spoiler is installed on the car by the manufacturer.

It is customary to distinguish the following types of spoiler:side ones, those that are installed on the bumper, there are roof spoilers and a rear spoiler. Side spoilers are door sill covers for cars. People usually call them thresholds-overlays. Spoilers that are designed to be installed on the bumper are popularly called bumper skirts. They are usually installed at the bottom.

Those spoilers that are installed on the roof of a car are usually found on crossovers and hatchbacks. They are mounted at the top of the back door. The rear spoiler is installed on sedans, on the trunk lid.

There is a type of spoiler that is installed on hatchbacks where the rear of the car has a gentle angle. For example this VAZ-2108. Here it is possible to install a rear spoiler below the rear window. They all differ in design and material used to make the spoiler.

2. How to choose a spoiler?

When choosing a spoiler, it is necessary to take into account its functional purpose. The fact is that its correct choice can affect the aerodynamics of the car body, while at the same time being a decoration.

Branded spoilers have better characteristics, so you need to buy a good model at an appropriate price. Spoiler installation should be done by professionals.

3. How to make a spoiler yourself?

It turns out that you can create a spoiler yourself. This requires durable material and other available means.

- polystyrene foam, the size of which is 100x100 cm and the thickness is 5 cm;

Paint that matches the color of the car - several cans are needed;

Sheet of iron, the thickness of which is not more than 1.5 mm;

Primer and putty - three jars;

Epoxy glue within two kilograms;

Brushes for applying glue;

Ruler;

Sandpaper;

Carbon fiber or fiberglass;

Neon lighting;

LEDs;

The principle of creating spoilers is the same. Its specificity of operation and functional purpose correlates with the right choice.

Brief step-by-step instructions

1) First you need to use polystyrene foam to cut out the “blade” of the wing. It is better to do this diagonally, since in this way it is necessary to keep within the dimensions.

2)

The next stage is making the mount. Plates are cut from a sheet of iron. Next you need to drill three millimeter holes. The distance between them should be no more than 30 mm. At this stage of work, we bend the plate in the form of the Latin letter L, since this is how it is convenient to fasten.

2)

The next stage is making the mount. Plates are cut from a sheet of iron. Next you need to drill three millimeter holes. The distance between them should be no more than 30 mm. At this stage of work, we bend the plate in the form of the Latin letter L, since this is how it is convenient to fasten.

Nuts with a diameter of 6 mm are welded into the base. Then they are carefully glued to foam blanks and covered with carbon fiber (fiberglass). At least three layers of fiberglass must be applied. During pasting it is necessary to maintain an interval. This is necessary for the glue to polymerize.

To speed up the process, warm up the glue a little. There is no need to prepare a lot of glue at once, since there will not be much consumption, and it will harden quickly. It washes well under running hot water. Foam chips tend to stick. To remove static voltage, you need to touch grounded objects.

3) If you decide to make side lights or a brake light, you need to put the wires in the glued spoiler, installing LEDs and neon lighting.

4) At this stage of work we prime the surface. Next we apply putty, clean it with sandpaper and prepare it for painting.

5) Painting the resulting workpiece.

6) The final stage is varnishing the spoiler. At the time of installation of each new part, a degreaser must be used.

7) The spoiler surface needs to be tidied up.

8) We install the spoiler in the previously prepared place.

Basic materials

The spoiler is usually made of metal. Aluminum works well. Racks are usually made from it. Sometimes steel and carbon are used. Nowadays metal spoilers are quite rare.

The spoiler is usually made of metal. Aluminum works well. Racks are usually made from it. Sometimes steel and carbon are used. Nowadays metal spoilers are quite rare.

The most common material for its production is fiberglass. It is based on synthetic resin. It is cheap and very easy to process. Its positive quality is good strength.

There are spoilers made of ABS plastic. It's cheap material. It is used as a result of mass production of spoilers. This plastic contains various impurities, so it is lightweight. However, a plastic spoiler is not durable, as it becomes quite fragile over time.

Appeared not long ago silicone spoilers and organosilicon polymers. They are popular due to ease of processing, good service life and excellent ductility.

Spoilers made of carbon are considered to be very expensive. The weight of this material is light, the strength indicators are excellent. The manufacturing process is labor-intensive. To create a convexity of the roof, a patterned guide made of chipboard is used.

Coloring

You don't need any special skills to paint a spoiler. You can do this yourself and even in a garage. Initially, the spoiler is prepared for painting by wiping it with a solvent. This way the transport soil is removed. Next, sandpaper is used.

You don't need any special skills to paint a spoiler. You can do this yourself and even in a garage. Initially, the spoiler is prepared for painting by wiping it with a solvent. This way the transport soil is removed. Next, sandpaper is used.

Thanks to it, the entire surface becomes matte. Particular attention must be paid to kinks and corners. Then we apply primer and paint, checking the cleanliness of the surface before doing so. The paint is usually matched to the color of the car. It is applied in thin layers. There should be several of them. A high-quality coating requires five to six stages of painting, since after the first pass there will not be an even layer.

When the paint is completely dry, the spoiler is varnished using a special aerosol can containing varnish. Check the can on a test surface, shaking it for three minutes before doing so. The varnish is also applied in an amount of approximately five layers, between which each subsequent layer is dried.

Individuality for a car has always been highly valued. However, the desired result cannot always be obtained quickly, efficiently and relatively inexpensively. To stylishly change the appearance of their favorite car, owners often use tuning body kits. Such decorations can not only make a car stand out from the crowd, but also protect it to some extent.

After all, it’s unlikely that anyone would covet a conspicuous car to steal it. It is easy to spot on the streets or parking lots. Therefore, by attaching a purchased bumper or installing a spoiler with your own hands, the owner not only makes the car stylish, but also hangs a kind of amulet on it.

A spoiler installed on the rear of a car is also called a wing.

With proper installation and certain calculations, the body kit part improves the aerodynamic properties of the car.

It also helps to slightly reduce fuel consumption; power is added by reducing air resistance.

Step-by-step manufacturing algorithm

To shape the wing, it is necessary to make a matrix. It will initially outline the contours of the product. Then the entire future structure is given rigidity. At the next stage, a primer, paint and a layer of automotive varnish are applied to the product. After manufacturing, the finished product is installed.

Foam spoiler

We will tell you step by step how to make a spoiler with your own hands. One of the most common frame bases for such a body kit is a strip of galvanized iron. Two L-shaped bends are made along both edges at 90 degrees. In the future, the entire structure will be fixed on such “legs”.

Step 1. Making a metal frame

Step 1. Making a metal frame  Step 2. Glue the foam

Step 2. Glue the foam

Step 4. Paint and varnish

Step 4. Paint and varnish  Step 5. Install on car

Step 5. Install on car

After this, the metal “skeleton” should be overgrown with foam “meat”. The white, lightweight material can be easily processed with any fine-tooth saw and polished with sandpaper.

After preparing the matrix, you will need to fix it with carbon fiber.

It is advisable to apply at least three layers. This will provide high-quality texture and additional rigidity to the product. It is advisable to take short breaks between laying layers to allow the resin to polymerize. In some cases, you can use an industrial hair dryer to speed up the process.

Installation of LED signal lighting is performed at this stage.

This way the wires will not be visible, they can be covered with layers of texture, and the LEDs can easily be mounted in any area.

After complete drying, you can prime the surface to impart adhesive properties. Irregularities must be filled with putty. This stage forms the final surface. After it there will only be a primer, applying several layers of paint and varnish.

Foam wing

To perform this operation, you must first cover the upper part of the trunk with plastic film. After this, fill the prepared surface with polyurethane foam and wait for it to dry. Next, using a sharply sharpened knife, we form the product. For finishing you will need to work with sandpaper.

Step 1. Foam the base

Step 1. Foam the base  Step 2. Cut out the blank

Step 2. Cut out the blank  Step 3. Apply carbon fiber

Step 3. Apply carbon fiber  Step 4. Install LEDs

Step 4. Install LEDs  Step 5. Sanding with sandpaper

Step 5. Sanding with sandpaper  Step 6. Paint and polish

Step 6. Paint and polish  Step 7. Installation on a car

Step 7. Installation on a car

Rigidity is also achieved using carbon fiber reinforced plastic (fiberglass).

At the final stages, the tuning part is puttied, and then primed and varnished.

Plaster spoiler

Duplication of spoilers can be done using plaster. To do this you will need an original tuning part. We wrap this spoiler with film and then place it in a foam box. Pour gypsum solution inside and wait for it to harden. Then we carefully get rid of the foam and saw the hardened plaster so as not to damage the original product.

Step 1. Making a mold for casting

Step 1. Making a mold for casting  Step 2. Lay the sample and fill it with plaster

Step 2. Lay the sample and fill it with plaster  Step 3. Sawing the shape and removing the workpiece

Step 3. Sawing the shape and removing the workpiece  Step 4. Pour the future spoiler into the mold and remove it after drying

Step 4. Pour the future spoiler into the mold and remove it after drying

After this we have a gypsum matrix. We put polyethylene in it as a gasket and fill in a portion of gypsum. Having opened the halves of the matrix after hardening, we take out the workpiece. Next, finishing, reinforcing and painting operations are carried out.

Conclusion

When manufacturing using any of the proposed methods, care must be taken to ensure that the structure has high-quality rigidity characteristics.

After all, during installation or further operation, a low-quality tuning product can not only fall apart itself, but also cause damage to a car, including someone else’s.

It all started with a trip to the auto store; I came in one day and saw an assortment of spoilers of various shapes, made of fiberglass and at reasonable prices (1400-2000 rubles), and, naturally, I liked one. I leave a deposit, go out, try it on in the car... bad luck, the length of the spoiler turned out to be 10 cm less than desired. It’s a shame, but I want to, and then different thoughts begin to creep in. One was like this - take this spoiler, cut it, make an insert of 10 cm, minimum time investment, but another 200 rubles are added to the cost of the spoiler, in the end we get 2200 (the spoiler we liked cost 2000 rubles) plus painting. The second thought is to do it completely yourself, while offhand we get the cost in the range of 700-1000 rubles. plus the shape of the spoiler can be made absolutely to your liking. Since my work schedule allows me to calmly go about my business and there are obvious savings, I decided to take on this business.

Unfortunately, my first step was taken in the direction of garbage containers, and all because after reading that you can take polyurethane foam sealant and squeeze a mold out of it, I went to the store. I read on the can that the volume of blown foam is about 20 liters, and after estimating how much I would need for the spoiler, I took one can...

Lay newspapers on the floor and let’s blow out the foam sealant into the blank. It turned out that what is written there - “foam yield is 20 liters” in practice is only 5 :(. I also had to buy a couple of large ones, on which 40 liters are written. I blew it as it is written in the attached instructions, the best result is a maximum of 10 liters. And the largest the drawback is that the more you heat the cylinder, the larger the pores in the frozen mass become, up to 5 cm. Having spent 5 cylinders, I gave up on this matter and concluded that if necessary; A little mold, then the method is not bad and it is better that the balloon is cold, and all this is not done in the heat. So I threw 500 rubles into the trash.

Well, I had to take foam; By the way, at first I wanted to use it, but then I abandoned this idea due to the large amount of debris, which is remarkably electrified and then sticks to everything.

So, a sheet of polystyrene foam 1 x 1 m thick, 5 cm thick (actually 4.5 cm, but that’s just minor things) was purchased. I cut out the wing blade diagonally, otherwise the sheet width was not enough. Next, I put off making the spoiler and took on something simpler - a stand for the number. Everyone knows that Japanese numbers are more square and smaller than Russian ones, so our numbers don’t look good in the places provided for them.

I cut out a blank, bought epoxy glue, but not the kind that comes in syringes for 40-150 rubles per 30 ml, but in a paper box. The quantity and manufacturer are different, but the box is the same. I didn’t have fiberglass; I didn’t know where to get it at that time. And here the old silk shirts came in handy. In general, after a couple of days I glued this stand, a few more days were spent on sanding and painting. I bought the paint in cans for 70 rubles each and covered it with the same varnish (it says Korean).

This is what happened:

Next... no, not a spoiler, but a lip, it’s easier to make (at least the one that turned out :)).

I took off the bumper, turned it over, and glued a blank out of foam plastic, which was weakly held on the bumper by silicone auto sealant. I tore off the blank and let’s give it a shape. After that, I wrapped it in plastic bags. I took the last tights from my friend, pulled them on and coated them with epoxy. After the two layers of tights had dried, I pulled the blank out of the lip (so that it would come out just like the bags are needed, epoxy does not stick to them). The epoxy will finally polymerize only after a few days. Of course, after a day it seems to be hard, but this is not always the case (my lip dried out for more than a week). Although it all depends on the amount of hardener, the more of it, the faster it polymerizes, but it also becomes more fragile, and it is better to add a plating agent for flexibility. Next, the glued lip is not yet strong, so I took the shirt again and glued it from the inside, 2 layers. The lip took two shirts. For strength in building materials, I bought reinforcing mesh and glued it with it. Well, then there was sanding, priming, painting.

Regarding the grip of the lip... on my first trip out of town I updated it :) (high speed + swelling on the road), in the 3rd photo it is just under repair.

Well, it came to the spoiler... I did the fastenings like this: I cut out 1.5 mm plates from sheet steel, drilled 3 mm holes in increments of 2-3 cm, for better gluing and reduced weight I bent them like an L, and welded two 6 mm nuts at the base. . Then I glued them into foam blanks, covered the wing blade with a couple of layers of fabric and assembled everything. And then, lo and behold, a man known under the nickname Paperman told me where there is fiberglass, and I’ll tell you that the only thing better than fiberglass is carbon fiber :) (if you can find it), it’s lighter and stronger. A few tips: as practice has shown, the lip glued together not from fiberglass will simply, like a cookie, and the reinforcing mesh doesn’t help :(, so be sure to look for fiberglass or carbon fiber, otherwise all your work will go down the drain after a small blow. The glue was applied with a brush, it then washes off remarkably well in a solvent, but it’s cheaper and odorless and can be washed under a hot stream water. Do not prepare a lot of glue at once, you may not have time to use it all (I used the largest portions at 200 ml). To prevent the foam sawdust from sticking to you, touch the water tap in the kitchen more often to remove the electricity.

I advise you to glue at least three layers of fiberglass (on the spoiler it turned out to be 4 + two layers of tights and mesh). Naturally, not all at once, but at intervals necessary for at least a small polymerization of the resin. By the way, epoxy glue polymerizes and does not dry. Moreover, this process accelerates several times at higher temperatures (up to 120 C, if I’m not mistaken), so the main thing for it is time and temperature.

Having glued the spoiler, I re-routed the wires in it, because in addition to the stop bar, I also wanted side lights. Then I skipped the puttying operation, but in vain, it takes a very long time to remove the surfaces with just a primer, and the resulting layer is too thick. Well, after suffering for almost a month with sanding, I started painting. There are generally two options: give it to specialists or paint it yourself. Of course, specialists will do better, but since everything is done with your own hands, why not paint it. I bought 3 cans of black spray paint and painted it.

The glass for the stop bar was made from epoxy. It would be better, of course, to find a rod of the appropriate size made of plexiglass or plexiglass (something transparent and fileable), but I could not find one.

Car before and after:

The costs are as follows (for the lip, license plate stand and spoiler) RUB:

Styrofoam - fit into one sheet, and there is still =70 left.

Fiberglass - it took about 2 m for 55 rubles = 110.

Fastenings and welding - scrap metal and oxygen from friends for beer = 20.

Shirts - I wanted to throw them away, my hand didn’t raise = 0.

LEDs 12 mm - 2x7=14.

Neon lighting in the spoiler = 300 *

.

Paint - it took two cans = 140.

Primer, 3 jars of 65 = 195.

Epoxy glue - I can’t say for sure, but approximately 2 kg (let’s say 8 bottles of 60 each) = 480.

Foam sealant = 540*

.

Wires - 2 meters = 10.

Chinese brushes - 3 pieces = 15.

Grid = 20.

Sandpaper = 100

Total 2014 rubles, although not counting the foam sealant and stop bar, then 1174. I did all this for 3 (three) months. So, if you have a lot of enthusiasm and patience for the cargo train, then go ahead :) But I’m still going to make the rear and front bumpers (the not very beautiful lip turned out, as they say, the first damn thing is lumpy), ears and maybe also a hood trim, but I won’t paint it myself.