When installing most metal structures, bending pipes at different angles is required. A ready-made device for this can be bought at hardware stores, but what if it is unlikely to be useful anymore? Is it worth spending money on a mechanism if it will later gather dust on a workshop shelf? The simplest and most logical solution is to build the device yourself. As for profile pipe make a pipe bender? Recommendations experienced craftsmen and video instructions in this article.

A self-made device will help you give the product any shape.

Rolled metal, bent at a certain angle, is necessary in many structures. Among them:

- engineering communications in residential buildings: water supply, sewerage, ventilation;

- fencing around the perimeter of the site;

- home and garden furniture;

- greenhouses;

- gazebos and canopies.

You can bend any rolled metal, the main thing is to use the right tool for this purpose. You can give the required shape not only steel structures, metal-plastic, copper, aluminum can be bent.

Helpful information! To select a pipe bender, you need to take into account not only the cross-section of the product, but also its profile. Simple round pipes can be bent much easier than profile ones. If handled incorrectly, the latter can become significantly deformed or even break.

To use the tool correctly, you need to carefully study the advice of professionals in the video. A do-it-yourself pipe bender for a profile pipe can be made in a simple, manual version or using hydraulics.

Hydraulic devices quickly and efficiently bend any metal parts.

A regular front pipe bender consists of the following elements:

- three metal shafts;

- drive chains;

- rotating axis;

- rotating mechanism;

- frames made of metal profile.

Sometimes the shafts are made of wood or plastic, but it is worth taking into account that such rollers will not cope with any pipe. If you do not calculate the resistance of the material, the shafts may simply collapse.

How does the profile bending device work?

Before you start making a homemade pipe bender for round pipe or profile, you need to understand the operating principle of the device. The action of the mechanism is based on rolling or rolling. This principle helps eliminate the risk of accidentally deforming and breaking the material. To give the metal the desired shape, it is inserted between the shafts and the handle of the device is turned. The result should be the desired bend.

Do-it-yourself pipe bender for a profile pipe: types of devices

The devices differ in purpose. There are devices for forming turns on steel, metal-plastic, copper, and aluminum products.

Devices can be portable or stationary. Portable models are convenient because they can be installed directly in the room where communications are being installed. Stationary machines are used in production.

Note! Improper use of the machine can lead to changes in the internal diameter of the pipes, wrinkles of the surface and changes in wall thickness.

Manual pipe bender

Soft materials, metal-plastic and copper, are easily bent with a hand-held device. Its design is quite primitive. The bender itself does not take up much space and can easily fit in a small workshop. In addition to the pipes themselves, you can bend reinforcement or rolled metal on it.

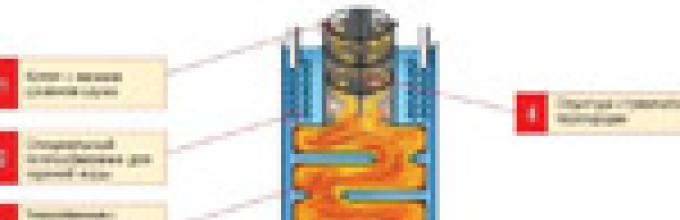

Hydraulic device

This device is capable of giving the desired shape to material with diameters up to four inches. The profile material, using hydraulics, can make intricate bends, repeating the topography of the wall.

Making a pipe bender with your own hands for a profile pipe: drawings and diagrams

The simplest device consists of a frame, slats, and two stops. If necessary, a hydraulic system can be added to it. Complex designs use a power supercharger and additional levers.

An example of a diagram of pipe benders for a profile pipe with your own hands:

Helpful information! Metal parts of the structure must be thoroughly lubricated to protect against rust. You can even provide a special compartment for automatic lubricant supply.

Model No. 1 – rental

Assembly algorithm:

- The metal base must be secured to a flat, durable surface and holes must be drilled at the ends.

- The steel rectangular plates must also be drilled to secure the rollers.

- Secure the plates to the base with nuts and bolts.

- Install rollers of the required size into the grooves and secure them firmly.

- In the center of the base, weld the stands for the central shaft and secure it with a stud and nut.

- Provide one shaft with a handle for turning.

Result: You should get a design like in the photo. You can not use a metal base, but attach the plates directly to the base.

Model No. 2

Another pipe bender for a profile pipe with your own hands, of a simpler design, will cope with products with a cross-section of two and a half centimeters.

Work order:

- It is necessary to make a device template on paper.

- From scraps of lumber, assemble the device according to the template, fastening the parts with self-tapping screws.

- Screw the resulting module to the wall. Screw a beam onto one side of the module for support.

Advice! When screwing parts, you need to focus on the diameter of the pipe. It should be easy to insert and lock into place.

Result in the photo:

Model No. 3

This version of a do-it-yourself pipe bender for a profile pipe is even simpler:

- A sheet of plywood is screwed to the wall, and the desired bend is depicted on it.

- Metal hooks are secured along the line with screws. Metal plates must be attached to each hook; they will additionally secure the material being bent.

- It is necessary to provide a stop for the end of the pipe.

Advice! If you don’t have enough strength to manually perform the desired bend, you can use a winch.

Result:

Application of hydraulics

For a hydraulic device you will need:

- rollers – 2 pieces;

- hydraulic jack;

- shoe;

- channel;

- steel plates.

The jack is fixed on the workbench. It will push the pipe into tight gripping rollers. If you prepare the videos different diameters, you can work with products of any size.

Related article:

More details about independent manufacturing a hydraulic pipe bender can be read on the pages of a famous online magazine HomeMyHome.ru. In addition, there you will find many useful information about the construction and renovation of your home.

Video: do-it-yourself manual pipe bender for a profile pipe

To construct a pipe bending device, you can use ready-made drawings. The video “How to make a pipe bender for a profile pipe with your own hands” will reflect the manufacturing procedure and how to use the resulting tool.

- To bend, rolled metal must be heated, especially on the outside of the diameter.

- To prevent deformation, the pipe must be filled with sand before bending.

- If you are not sure of the result, don’t try it. Sometimes it is easier to buy ready-made bends and weld them to the pipe than to correctly give it the desired shape.

Drawing conclusions

It is quite possible to make a simple device for bending rolled metal with your own hands. If you need to manufacture a complex configuration metal structure, it is better to use the rolling method. For a couple of simple bends, a device using hooks is suitable.

It is worth remembering that the wrong ratio of force and excessive haste can lead to irreparable deformation of the material.

You might also be interested in:

How to correctly transmit meter readings for electricity: different ways and their benefits

How to correctly transmit meter readings for electricity: different ways and their benefits

How to use a multimeter correctly: simple instructions

How to use a multimeter correctly: simple instructions

We will send the material to you by e-mail

In some cases, it becomes necessary to bend profile pipes into an arc shape. This will require special skills and some tools. Special devices will help you create a pipe bender for a profile pipe with your own hands. For such products you do not need to purchase expensive materials and equipment. Read more in the material below.

Homemade unit option

Before you start producing a pipe bender for a profile pipe with your own hands, you need to find out why such equipment is required. A pipe bender is a device that helps bend a selected part from different materials with the required radius.

The element can be made of steel, plastic or aluminum, and also be profiled. The bend angle varies from 0 to 180 degrees.

Helpful information! The devices made are various types, so before making them it is worth choosing the most optimal option.

Types of pipe benders

Industrial devices can be classified by bending method or drive type.

Homemade devices can be made from inexpensive and unnecessary materials

Classification of devices by drive type

On a production scale, various types of machines are used. They will help you make suitable types of pipe benders with your own hands - drawings and professional diagrams.

The following types of devices are distinguished:

- Hydraulic machines can be stationary or manual. They allow you to bend parts with a diameter of 3 inches. Apply similar devices in production. With their help, huge amounts of work are performed.

- Electromechanical-type designs are suitable for processing any highways. Electronic capabilities help to accurately calculate the bending angle and the required pressing force.

- Manual devices are used for bending products with a small diameter.

Helpful information! It is important to consider that thermal effects on profile elements cause changes in internal structure material. In this case, the strength properties may decrease. Repeated bending can lead to structural failure.

Device options based on pipe bending method

The part can be bent in various ways. Pipe benders are classified according to the bending method:

- Segmental ones are equipped with a special mechanism that allows you to pull the line and bend it at a certain angle.

- Crossbow devices are equipped with a special device, which is a bending element.

- Spring devices are equipped with special springs that help bend plastic products.

Helpful information! The size of the possible angle depends on the characteristics of the product. At independent work, you should adhere to the minimum value of the bend radius. If you bend it over a greater distance, then over time such a highway may become deformed.

Self-production of the device

There are many auxiliary materials that tell you how to make a pipe bender for a profile pipe with your own hands: drawings, videos and professional diagrams will help you create a high-quality design.

Worth considering simple options homemade equipment. You can design a simple mechanism using a template and a special radius. Similar technologies make it possible to process aluminum and steel lines. The template can be created from ordinary boards. In this case, parts with a larger diameter than the pipes that need to be bent are selected. The selected boards must be securely fastened so that the pipe cannot jump out of them. To create a rounded gutter, the boards are cut to the required shape. Wooden product is attached to a solid base and a stop is mounted nearby for fastening the workpiece.

Rolling unit drawing

Self-made products are able to bend even elements with thick walls. To do this you will need to use a winch. When using a profile line, bevels are not used when processing boards. The product is secured with special limiting devices.

It is also possible to create a rolling version of a pipe bender from wood, but this will require special rollers made of polyurethane or bearings. For products made from softer materials, you can make wooden bending units, while for harder lines you will need metal parts.

Parts required for installation

Helpful information! When making a machine yourself, individual parts are made of metal. Before installation, it is worth calculating the strength of the parts being processed and the quality of the manufacturing material so that the structure can withstand their processing.

Do-it-yourself hydraulic pipe bender for a profile pipe: drawings and circuit features

The creation of a hydraulic structure requires special attention. To perform such an installation you will need a channel, a jack with a special drive, rollers and a shoe. It is necessary to select metal sheets whose thickness is more than 3 mm.

Using welding units, a system in the shape of a rectangle is made from a durable channel element. Its height should be the same as that of the jack. This element should act as a pusher. It is important to select high-quality rollers to accurately grip the selected pipes.

Such a hydraulic unit has many advantages. This is ease of manufacture and low cost of auxiliary models. Using such an installation, you can bend any pipes even when cold. The video below will show you in detail how to make a pipe bender for a profile pipe with your own hands.

Helpful information! A profile pipe with a square cross-section will be easier to bend close to the ends of the line.

Video: example of a self-made hydraulic pipe bender

Do-it-yourself rolling manual pipe bender for a profile pipe: video and diagrams

The selected element is processed on a rolling machine in a certain way. The part is mounted on rollers and secured in the desired position. When the handle moves, the chain moves and moves the shafts. As a result, the profile pipe bends in the specified and required direction.

To create a rental unit you will need to perform the following steps:

- Clips and special rollers for the bearing mechanism are machined. If you have drawings, you can order similar work from a specialist.

Rollers are made on a regular lathe

- The unit has three shafts.

- The design of the screw mechanism is being manufactured. A shelf is made from a channel. Holes are made in it for fastening the shafts, and threads are also cut to adjust the pressure shaft.

Related articles:

There are several types of pipe benders, which differ in mechanism and principle of operation: hydraulic and pneumatic. Factory units that are driven by both types of drives do a good job of creating bends. Unfortunately, not everyone can use such devices or purchase a factory version, and mastering bending technology on factory machines without experience is problematic. What kind of pipe benders can you make with your own hands? What are the common bending techniques?

Manual homemade pipe bender for profile pipes

The homemade profile pipe bender is available in several variations. It all depends on the materials that are available when creating the equipment.

The most common is the frontal one, for the manufacture of which you will need:

- three shafts/rollers – cylindrical in shape made of metal;

- chain;

- axis of rotation;

- drive mechanism;

- metal profiles for the frame.

When creating a machine with your own hands, you make the structure or some elements (rollers) from wood or polyurethane. During operation, it is necessary to calculate the strength of pipes (manufacturing material) that will undergo deformation. Otherwise the structure will not hold up.

Manual bending technology

In the process of bending a profile pipe in homemade machine The principle of rolling/rolling is carried out. Pipe bending using this method avoids kinks and damage. The result is an exact correspondence of the desired angle to the degree and size. In the unit, the pipe is inserted between the rollers and bends when the handle is rotated.

Stages of assembling a manual pipe bender

How to assemble a manual pipe bender:

- Prepare metal carcass to install components. The structure is secured by welding and bolted to ensure the strength of the entire equipment.

- Installation of the rotation axis and shafts, two of which are mounted above the third. Here the bending radius of the pipe depends on the distance at which the two lower cylinders are located from each other. Therefore, to adjust the deformation angle, install the rollers and stopper.

- The rotating mechanism is driven by a chain. The presence or absence of gears is taken into account here. There are only three of them. A chain from an old car, which is mounted on the shafts, is suitable.

- Attach a handle to one of the shafts. The element will create a torque force.

Video instruction. How to make a manual pipe bender

DIY rolling machine for bending profile pipes

To manufacture a rolling machine for bending profile pipes you will need:

- jack;

- for the frame: metal profiles and shelf;

- 4 high-strength springs;

- 3 shafts;

- chain and other elements.

Roll bending technology

During the bending process in the machine, the pipe is deformed at a given location. The pipe rests on the side rollers, a third one is lowered from above and thus the product is fixed. When the handle rotates, the chain sets the shafts in motion, and the pipe bends at the desired angle.

How to make your own rolling pipe bender

How to make a rolling pipe bender:

- The pressure shaft consists of gears, rings and bearings secured through a key. Therefore, the main thing in the assembly process is turning the rollers and bearing races. The size of the shafts must correspond to the bearings and sprockets. The turning process is entrusted to the turner based on the drawings. There are three shafts, two of which are located on the sides, and the third is suspended on springs.

- The next step is to drill holes and cut threads in the rings (for making grooves, threads for clamping bolts) with your own hands.

- Preparing a shelf from a channel - drill holes and cut threads to install the pressure shaft.

- The last stage is welding and installation work the entire structure. First, the frame (legs) is installed.

- Next, hang the shelf with the pressure shaft on springs and mount the side support shafts, which are connected with a chain. At the end, attach the handle to one of the side support shafts and mount the jack.

Aspects of work:

- the pressure shaft is screwed through keys to the shelf;

- The “suspended” pressure shaft is installed on a shelf. Nuts for the springs are welded to this base. Subsequently, the platform is turned over and attached to springs;

- when tensioning chains, a magnetic corner is used as a holder;

- in the process of screwing the sprockets, install keys prepared from an engraver;

- the rotation handle is made with a rotating tube;

- The jack is mounted on a “suspended” platform using bolts and welding.

How to make a hydraulic pipe bender at home

The hydraulic pipe bender for profile pipes is equipped with a hydraulic cylinder, bars, a pressure device and pipe stops. Making such a unit at home is a labor-intensive process.

Equipment details:

- hydraulic jack (not less than 5 tons);

- shoe;

- several rollers (2-3);

- channel;

- metal plates and other parts.

Hydraulic bending technology

The bending process involves deforming a given section of pipe using a hydraulically driven jack. The pipe is inserted into the shoe and both ends are secured. Operate the jack by turning the handle slowly. The force created by the hydraulic drive is transmitted to the roller - the pipe is bent at the desired angle. The work can be stopped at any time; the pipe can be pulled out by making a couple of turns of the handle in the opposite direction, that is, releasing the pressure of the roller.

How to make a hydraulic bending machine

We make a hydraulic bending machine with our own hands:

- A channel structure is pre-prepared where the shoe and rollers will be located. Then the frame of the machine is made of similar metal.

- The last platform of the structure is reinforced with metal plates. Subsequently, a jack will be mounted on this shelf. Secure the device with bolts and attach the handle.

- The difficulty is finding or making rollers that should wrap around the pipe. The parts are mounted in a rectangular channel at an equal height. The shoe is installed lower. The arrangement of the parts determines the specified bend radius.

- The rollers and shoe are secured with bolts. The holes are prepared in advance.

Video instruction. How to make a hydraulic pipe bender

Bending profile pipes using a homemade machine

When bending pipes, it is necessary to know the diameter of the material and the principles of the process. This will ensure correct deformation of the material without overload or kinks. On machines using hydraulics, it is possible to bend a section of pipe with heating, which allows you to bend products with large wall thicknesses, made of durable alloys and polymer materials.

Hot and cold pipe bending methods

Pipe deformation is carried out in two ways:

- cold;

- hot.

Cold bending is used for pipes made of plastic material. As a rule, these are small-sized products made of copper, aluminum and other materials (except cast iron), metal-plastic. The process is carried out using machines or a mechanical pipe bender. For better bending, sand, salt, or oil and water (ice) are poured into the pipe before deformation.

Tatyana Pronina, expert

The second method is used to deform pipes with increased ring rigidity (stainless steel, etc.). The method can be used for all types of pipes, except metal-plastic.

Table of minimum pipe bending radii

Where the smallest bending radius is R, the pipe diameter in mm is d, the minimum length of the straight section is Lmin.

How to make a template for bending pipes along a radius

The simplest method is to bend the pipe according to a template. The principle is to deform the material by applying wooden structure with a radius of curvature. The method is suitable for aluminum and steel pipes with small wall thickness.

The template is cut out from wooden boards, which are fastened together with bolts or other most in a convenient way. The entire structure is bolted to a table or other stable base.

The thickness of the template, where the pipe is directly applied, is several centimeters greater than the diameter of the pipe being bent. The end of this part (the edge of the template) is cut at an angle so that the pipe does not slide off the ledge.

An emphasis is mounted on the template. A pipe is inserted between it and the base of the template and gently pressed - the material bends.

- If you are assembling a manual rolling pipe bender for profile materials, then you can not use sprockets, but build a structure with a drive on one roller. But the mechanism will periodically slip. The clamping screw can be replaced with a jack.

- When making the template, use hooks attached to the wood to prevent the pipe from slipping.

- If you have to bend a pipe under a large radius, it is better to make a unit with three rollers.

- The greater the distance between the rollers, the less force is applied for bending. To change the bending radius, first provide for the possibility of the rollers moving horizontally relative to each other.

Video lesson on bending profile pipes

Bending profile pipes at home is carried out using various pipe benders, assembled with your own hands. Professional engineers and hobbyists are increasingly improving homemade equipment and share their discoveries online.

Do you have your own method for bending profile pipes? What tools have you collected yourself? Share with us in the comments.

Making a pipe bender for a profile pipe with your own hands is not very difficult; for this you need to stock up on drawings, a small amount of metal and patience.

There are many different types of pipe benders; in this article we will look at an example of creating a rolling profile bender.

In contact with

Classmates

Application of pipe bender

A profile bender will allow you to easily make a beautiful shady canopy for the yard or for a car

With the help of such a device it is easy to create metal structures of various shapes.

Smooth, rounded lines look more attractive on a variety of products than sharp ones.

Tables with metal legs fancy shapes, park benches and much more are made using this tool.

DIY profile pipe bender

There are pipe benders different types and have Various types mechanism. We will look at a rolling pipe bender with three rollers and a manual drive.

“Rolled” means that the workpiece that is to be bent is not fixed in the mechanism, but changes its diameter by rolling along its entire plane. This approach makes it possible to obtain workpieces of practically unlimited length and a very large radius.

In order to obtain a small but even bend along the entire length of the workpiece, you need a rolling pipe bender.

The pipe bender drive can be mechanical (manual) or machine (hydraulic or electric). To reduce the cost and simplicity of the design, it is better to use a manual drive, this will allow more precise control of the process of creating a workpiece on initial stages and adjust your actions as you work.

Note: manual drive will not require any special physical skills from you.

The design of the pipe bender under consideration involves the use of three rollers, two of them are the main ones, they support the workpiece and are fixed depending on the required radius, at an equal distance from the central (pressure) roller. The pressure roller is located in the center and is designed to apply a certain pressure to the workpiece to bend the product.

Drawing of a rolling pipe bender

The figure shows an approximate layout of the pressure (3) and main (1,2) rollers. This scheme is quite functional, but the lower location of the pressure roller imposes restrictions: for example, the bending angle will be directed downward, and therefore the long workpiece will rest against the base of the entire structure or the floor.

You can avoid this by installing the profile bender on a special frame; this will make it possible to make large angles, but still a very long pipe can rest against the floor, and it is impossible to endlessly lift the entire structure up.

The design of a homemade pipe bender with an upper pressure roller does not have the disadvantages of the previous version: pressure roller “3” presses the workpiece, which is located on rollers “1” and “2” from top to bottom.

As a result, the pipe bends in such a way that the edges point upward. If you use a pipe bender outdoors, you can bend a pipe of almost infinite length.

As for the “4” clamping mechanism, it is often made using a screw axle from an old vice or another strong screw. You can also use various jacks. If you took a manual jack, then the entire structure above the work area will be occupied by a large “superstructure” for installing the jack; in this case, it is easier to remove the mechanism from it and install it vertically on the product.

It makes sense to use a hydraulic jack if the profile pipe intended for bending has a very thick wall. In this case, manual effort may not be enough and you will need hydraulic assistance.

Note: power hydraulic jack must be at least 5 tons, otherwise difficulties may arise.

The rolling mechanism “5” must provide the pipe with movement for smooth bending in the entire plane. In the drawing, the handle of the mechanism is firmly fixed to the pressure roller, and when rotated, it rotates the roller itself, which in turn moves the pipe. This approach has a right to exist, but it also has disadvantages.

When you need to bend a pipe with a thick wall, the force applied to the pressure roller can be so strong that it will be problematic to turn the workpiece or the roller may simply slip.

In this case, the mechanism is transferred to support rollers “1-2”, bicycle sprockets are installed on the rollers and connected with a chain, and the handle is installed either on one of the rollers or on an additional third roller, which can act as a “tensioner” for the connecting chain (as shown in the picture).

Take note: choose the size of the product based on your personal needs, but remember the safety margin.

Tools and materials

In order to make a pipe bender yourself, you will need some basic set of tools, such as:

- Welding.

- Bulgarian.

- Roulette.

- Marker.

- Corner.

- Gloves.

In addition to tools, you will also need a certain set of materials:

- sheet metal (minimum 4 millimeters) or square pipe with a wall of 3 millimeters or more;

- rolling rollers;

- bearings 6 pcs. (along the diameter of the roller axis);

- bolts 8 pieces;

- chain;

- clamping mechanism (strong screw or jack).

Take note: if you order rollers from a turner, spare no expense and turn several sets with an internal groove, under different widths profile. Such a limiter will not allow your workpiece to move in the plane and guarantees you an even pipe at the exit. It is better to buy bearings that have their own housing.

Build process

- The first step is to create the frame of the future product; you should not skimp on metal. If you use metal that is too thin, your pipe bender itself may bend, and then the pipe will turn out uneven, or the pipe bender will stop working properly altogether.

- We prepare the frame for installing rollers and mechanisms on it: we drill slots and holes for installing parts, and weld the necessary fasteners.

- We install rollers and a clamping mechanism.

- The last stage is to install a chain drive on our mechanism.

That's all, a pipe bender for a profile pipe with your own hands is ready for use. You can take the first pipe and test the effectiveness of the device by bending it. If everything is in order and no flaws have been identified, then paint your new profile bender to protect it from corrosion, and it will serve you for many years. So, at home, you can make a tool with your own hands that will make your work easier.

How to make a pipe bender for a profile pipe with your own hands, watch the video:

In contact with

See inaccuracies, incomplete or incorrect information? Do you know how to make an article better?

Would you like to suggest photos on the topic for publication?

Please help us make the site better! Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!

To every owner of a big garden plot or a small dacha, at least once in your life (at least) you may need a pipe bender - a device for bending a profile pipe.

For example, this could be a blank for a greenhouse frame or canopy, gazebo, or any other metal structure.

Metal sales centers and other industries usually use factory-made devices, but this pleasure is far from cheap. To save your budget for more pleasant expenses, it is more profitable to start making the device manually, on your own.

For this design, as they say, “you don’t need a lot of intelligence,” and there won’t be a shortage of parts either; you can actually create the drawings of a pipe bender yourself.

Pipe bender options

You can bend the pipe using the “home” method, fill the pipe with sand, heat it until red with a blowtorch, or gas burner, then bend the pipe. This method is not recognized as a priority among craftsmen; it is labor-intensive and does not provide sufficient accuracy; creases and deformations may also appear.

To get perfect bent pipe, in compliance with standards and given parameters To avoid causing damage to the source material, craftsmen use specialized pipe benders in their work.

Lever-type pipe benders have become very popular. This elementary invention works on the principle of a “lever” - the force is concentrated in a certain place, and the bend merges with the shape of the template you created, which can most often be removed and replaced with another.

Most often, the kit of such structures includes a couple of additional templates for pipes of different diameters. There are units of similar design, manual pipe benders, drone or crossbow benders, they allow you to bend short sections of round steel pipes, subjecting them only to cold processing.

Crossbow devices are very compact and are valued in the field of installation and engineering communications.

What is the job of a pipe bender?

The principle of operation is completely simple, it consists in heating the pipe, the pipe heats up red and becomes very plastic, malleable to change. Each type of pipe bender has its own range of capabilities.

The main functions are the quality of bending and the ability to bend pipes different sizes and diameter.

With the help of additional rolling devices, a bend of a larger diameter is achieved. The device operates using shafts, there are three of them in the set.

Guides and pressure. The pipe passes through moving elements, the degree of bending is set by the force of the pressure roller. If the radius of curvature of the finished product is small, the procedure should be repeated.

Bending a pipe according to a template

In most cases, the simplest option, suitable for absolutely all craftsmen, even beginners, is a wooden template. Boards are selected according to the thickness of the pipes being bent; be sure to leave a couple of centimeters of board space.

To prevent the profile from moving off the template during operation, a slope is left at the ends. The template is rigidly fixed to the floor or other stable surface, and a stop for the pipe is installed nearby.

The profile is inserted into the gap between the template and the stop, smoothly and carefully press on its other end, pressing the pipe against the template. A winch or lever will make the job easier.

A huge advantage of this process is cost savings and ease of execution.

Note!

Any device has disadvantages, and this method is no exception. The bend is inaccurate, of poor quality, and the template will be disposable (apply only to one pipe diameter).

Snail pipe bender

When stamping identical blanks in large quantities with a small radius of curvature, a snail pipe bender will become indispensable.

Its advantage is its small size and ease of operation. The disadvantage will be the limitation of the radius of curvature, but not large sizes.

Rolling pipe benders

The niche of versatility and practicality is occupied by hand-made devices - rolling pipe benders ( bending machines), on such machines you can make any bending angle.

The configuration is not particularly different from other models; they also have a base and shafts. The movable roller presses the pipe, and it is pulled through by the rotation of the drive shafts.

Note!

Pressure can be increased using a winch, levers or electric drive. However, for the production of a house, such a design is quite complex to implement.

To reproduce such a unit, a lot of turning and welding will be required. If you decide to make such a model, it will serve you for a long time and will delight you with its functionality.

How to make a pipe bender with your own hands, the question is modern world quite relevant. To make the task easier, you can find a photo of a pipe bender on the Internet to roughly understand what it should look like.

There are also many pipe bender drawings that are easy to use. After reviewing all the information and assessing your strength and the availability of the necessary components, calmly get to work.

DIY pipe bender photo

Note!