If we consider metal coverings, seam roofing is distinguished by its style. Its installation involves joining the metal into special folds, this is how a sealed and durable flooring is obtained. As a rule, when purchasing a material, instructions for use are attached to it, and if not, then this article will help you understand all the difficulties.

Pros and cons of seam covering

Looking at the finished seam roof, you will immediately be able to notice its unusual appearance compared to other coverings. Essentially, the roof plane is filled with ordinary even sheets

metal, and with the help of a folding machine they are connected together. If you don't want to deal with a complicated device, you can purchase a self-latching product.

- So, what are the advantages of this roof?

- The metal coating is highly durable and durable

- The low weight of the material allows the use of a lightweight rafter system

- Construction will be a cost-effective activity

- Low cost

- Wide choice of colors

Atmospheric precipitation can be easily removed from a smooth surface Despite such a number positive aspects

- , the coating in question has significant disadvantages, namely:

- Metal does not protect against noise in any way, and in some cases, on the contrary, increases it. For example, when raindrops fall, you will hear a lot of noise, however, for some residents this drawback is an attractive side

- When installing a seam surface, you will need special devices to create high-quality seams, and this costs a lot. The only acceptable solution to this problem is to hire a team of roofers, but since the roof is losing its popularity, it is not so easy to find them. Plain metal will not add aesthetics to the roofing surface, and if you want beautiful roof

- , then you will have to purchase copper, which is several times more expensive.

A seam roof accumulates electrical voltage over time, which can be released during a thunderstorm; therefore, a lightning rod must be installed on the uppermost section of the roof.

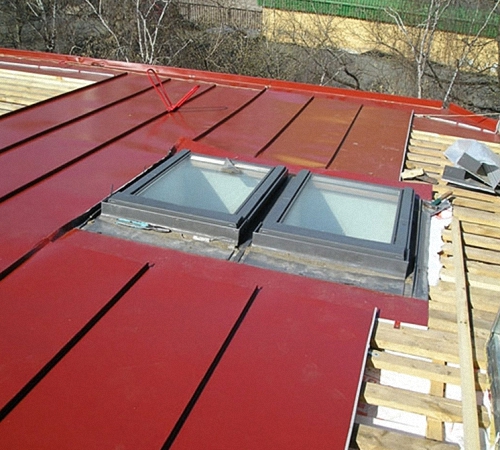

It is immediately worth noting that metal sheets can be laid on roofs with a slope of about 14 degrees. Of course, there are also concessions under which the minimum threshold can drop to 7 degrees. If this is exactly the situation you have, then you need to create double folds instead of standard seams and lay the metal on a continuous sheathing. On flat roofs, all joints must be coated with sealants.

To create a warm and high-quality roof, you need to take care of the thermal insulation and waterproofing layer and, in addition, create a good natural ventilation. Some developers do not want to install additional layers of sound insulation because they like the sound of rain, but for the vast majority this action is necessary.

This can be done by insulating the inside of the roofing pie, or along the interfloor ceiling.

When installing roofing sheets, identical material must be used as fasteners, i.e. if the coating is made of galvanized steel, then the self-tapping screws should be made from this raw material. In addition, they must be equipped with a rubber lining to prevent the mounting points from leaking. If within several decades the roof begins to rattle when there are gusts of wind, then you should pay attention to these details.

Because sheet metal is not a very heavy coating, then the sheathing can be done in any way, namely: solid or discharged. If everything is clear with the solid one, then the pitch of the elements of the discharged system should be selected so that the sheets do not sag anywhere. As a rule, metal roofs last up to 100 years, but this is subject to compliance with all construction norms and rules, as well as high-quality preventive inspections.

Further in the article you will learn how to install a seam roof, whether it is possible to carry out installation alone, installation instructions and useful video materials.

Types of folded seams

To make the installation process easier, the metal sheets are collected into one large sheet on the ground. The resulting plate is called a picture. Seam roofing has only 4 ways of attaching these sheets to each other.

- Single (standing, lying)

- Double (standing, lying)

If we consider these types of better tightness, then the maximum indicators are observed in the double rebated fold. This surface is practically monolithic and is suitable for installing flat roofs. Well, as you understand, the weakest on this list is considered to be a single standing seam. It is used on roofs with a slope of 15 degrees.

Seam coating can be created from the following metals:

- The most cost-effective product is galvanized steel sheet. It is very easy to install, and to protect the material, ordinary paint is used, which lasts for 8-10 years. Of course, it is not necessary to paint the roof, but after a few years, stains will appear on it and corrosion will begin. The service life of a galvanized steel roof is 20 years without repair.

- Steel coated with polymer film. This roofing sheet can easily withstand prolonged exposure to sunlight, and due to its bright structure it is a more attractive material.

- The most common metal is considered to be aluminum. The service life of such metal is about 80 years. This is a very good indicator for a relatively inexpensive coating.

- Residents of a private house with good income can afford to equip the roof of their house with copper sheets. This material is very resistant to corrosion and only gains strength characteristics over time. Usually, copper roofs last up to 200 years, which is far beyond the operation of the building itself.

- If you do not need a durable, but the most durable roof, then I draw your attention to an alloy of zinc and titanium. Sheets made of this material are resistant to corrosion and sudden temperature changes, they are distinguished by their rigidity and can last on the roof for more than 100 years.

The choice of material will depend on the needs of the resident and the functional purpose of the building itself, for example, if the building is temporary, then it is better not to spend expensive products on it.

Installation of seam roofing

The entire process of installing this roofing can be divided into several stages:

- Preparatory work

- Installation of cornice and wind strips

- Installation of additional elements

So, now in more detail about each of the points.

Preparatory processes

At this stage, it is very important to buy a quality product and acquire a good tool.

The following products are used for surface construction:

- Rolled or sheet metal that will be laid on the roof

- Additional elements (eaves strips, ridge, valley, etc.)

- Beams with a section of 5x5 centimeters and boards of suitable sizes

- Gutter details

- Fastening elements, including clamps. If the length of your roof slope exceeds 10 meters, then sliding ones are used, and under other conditions - fixed ones.

Seam roofing has unclear dimensions. It can be created to any length and width, but the best quality surface is obtained when the sheet of metal is completely covered by the slope. As you understand, the amount of materials will depend entirely on the size of your roof. In order to reduce its waste, it is best to create a kind of drawing in which all the smallest details will be taken into account; in addition, rolled metal has the least waste.

The roofer’s main tool when creating a seam roof is, of course, a device that creates such seams, but for high-quality flooring you will need to use some more devices, namely:

- Scissors for cutting metal (alternatively, you can use electric scissors or a nibbler)

- Measuring device

- Regulators (level, plumb)

- Wood saw

- Drill with all attachments

- Kiyanka

- Gun with sealant

- Hammer

- Other

If you are wondering what the last point involves, I will answer it as follows. In construction, even the same type of construction is not the same, and in seemingly identical situations you can use different tools.

Assembly of the rafter system, installation of waterproofing and sheathing

Since metal sheets have a small mass, there is no need to arrange rafter legs close to each other. After determining the optimal step, a waterproofing membrane is attached on top of them, and in order for this work to proceed as quickly and efficiently as possible, it is necessary to acquire counter-rails in advance (the cross-section must be at least 30x60 millimeters). As for their length, it must correspond to the width of the rolled membrane, which is 1.5 meters. As a rule, a sealant is placed under the counters, which acts as a sealant and blocks the access of moisture through the holes left as a result of fastening.

IMPORTANT: All wooden elements that are used in the rafter system must be processed special solutions. Antiseptics and fire retardants will reliably protect lumber from rotting and fire.

The installation of the waterproofing sheet should run clearly from left to right and move from bottom to top. After attaching the first strip of material, the second is laid with an overlap of 15 centimeters. Construction tape or butyl tape is used as a joining material. In addition to its main task, this material creates a barrier to heat escape, which has a positive effect on the entire roof. It is worth noting that Bottom part The waterproofing membrane must be discharged to the upper part of the overhang. Thus, the accumulated moisture on the material will be drained into the drainage system, which is installed before the start of this process.

As an alternative to standard lumber sheathing, you can use a steel profile, but, as a rule, everyone refuses this. Wooden elements discharged sheathing must have a reliable cross-section: 30x100 or 50x100 millimeters. In the case of a copper roof, the base for it is created solid, and all other materials can be laid on a thin one, the pitch of the boards of which is 20-25 centimeters. As additional protection, the valley of the seam roof and the edges of the slopes are equipped with continuous sheathing.

Installation of roofing strips

One of the nuances of a seam roof is that the lower part of the roof in contact with the drainage system must be mounted before the main elements. This can be done by installing a cornice board, but if you have not yet purchased this element, you can create a temporary alternative. To do this, a corner strip is placed on the overhang, and on top of it, with an overlap of 2 centimeters, a sheet of metal is attached, which will serve as a moisture collector.

After working with water drainage, you can begin to create a base for the wind slats. Ordinary beams with a cross section of 30x50 millimeters will do for this.

Assembling the paintings and attaching them to the slope

Laying metal sheets using the seam method can be carried out in only two ways:

- Traditional method. The paintings are assembled on the ground and, after being lifted, secured to the slope. The symmetrical arrangement allows you to create a beautiful appearance of the roof as a whole. The entire process of the device can be described in a few words. The paintings are lifted onto the roof slope, laid out in the required order and connected using a single or double seam. In the case of metal flooring for large volumes, in addition to vertical seams, horizontal ones are also used.

- Modern method. This technology has some difficulties, since metal in rolls is used to construct the flooring. Before laying, it is cut into the required patterns, maintaining the required length and creating bends for future seams. As a rule, a double fold is created on such metal, followed by treatment with a sealant.

If you are going to do everything yourself, then the most suitable option will be the purchase of metal sheets with a self-latching mechanism.

An important nuance is the delivery of material to the roof surface. It must be carried out in accordance with all rules and regulations. The most important of them are:

- Roofing work should not be carried out in windy weather.

- All material must be delivered one piece at a time on the roof

- The work must involve 3 people. Two of which will serve and one will receive

- For large product weights, use long logs

After the material is delivered to the surface, you can begin installing the roofing.

The whole process begins with the so-called starting picture. It is attached to the wind strip using self-tapping screws so that a protrusion is formed. Experienced roofers advise not to tighten the screw all the way and leave a turn somewhere. This will prevent the metal sheet from deforming during the heating process. When using material without self-latching mechanisms, fastening to the sheathing is done using clamps.

If the length of the sheets was not chosen correctly, and it is much shorter than the slope, then the flooring should be laid on the left. The last sheet of metal should be trimmed so that it protrudes beyond its limits by 30 centimeters. After which this edge is bent upward.

If you have any questions, watch how to install a seam roof in this video:

Installation of additional elements

The work on installing the roof is completed with the installation of additional elements, namely: the ridge, protective aprons, valleys and other less important elements.

Since the roof is metal, it is necessary to take care high-quality ventilation. As a rule, most developers use ventilated ridges and this is the most rational thing to do. Often on metal roofs in attic spaces the air is very humidified, therefore, the metal will very soon begin to corrode. In order to remove moistened vapors, this element is mounted.

The ridge is placed exactly on the parts of the paintings that are bent upwards, and if they are absent on the slope, then the fastening occurs using a special Z-bar. Her body has perforations, which has a positive effect on ventilation in general. The ridge element, as a rule, is selected to match the architectural design. It is produced semicircular, triangular and flat.

If the roof of your house has a complex rafter system, then an angle called a valley is formed at the junction of the planes. Such elements cannot be ignored, as they are most susceptible to moisture. In addition to the water drain, the valley must be equipped with a continuous sheathing and a waterproofing layer, just like the overhangs of the roof plane. fasten waterproofing material It is best to use a construction stapler, and for greater sealing, the joints are coated with mastic.

Repair work on seam roofing

Any responsible owner of a private home knows that annual preventive inspections of the roofing surface are an integral part of living. Their minimal amount is 2 times, one of which occurs in the warm part of spring (when the snow on the roof begins to melt) and in autumn (to prepare the building for wintering). During this process, deficiencies that may cause leaks should be identified.

It is worth noting that in most cases the reasons are minor and may require replacing the sealant or fastening elements of the paintings, but if you ignore annual preventive inspections, you may have to replace several paintings.

As you already know, aluminum and galvanized surfaces are attractive to developers. The fact is that they are the easiest to repair. To seal the problem area, you can use a patch device. By the way, if you are going to do this, then after finishing the process do not forget to protect the seams you just created.

The most in a simple way Repairing an aluminum roof is considered a patch using self-tapping screws. To do this, you need to find a piece of material that will cover the problem area by 10 centimeters on each side. Next, we apply it to the base and secure it with self-tapping screws. After this, special roofing glue is poured into the seams. The procedure for filling the seams is repeated several times throughout the day.

The most common causes of leaks are:

- Large pitch of sheathing elements, which causes sagging of sheets

- Over time rafter system changed its geometry and subjected the metal sheets to deformation

- Violation of seam tightness

- The metal coating has begun to corrode or is mechanically damaged

In no case should leaks be ignored, as this will lead to rotting of the rafter system, therefore, the entire roof will have to be repaired, or rather, rebuilt.

During operation, there may be times when, due to strong gusts of wind, roofing sheets begin to rattle. The reason for this lies in the fastening elements. Check them and replace them with new ones if necessary.

If after reading this article you still do not understand how a seam roof is laid, and the video did not help, then the only rational decision specialists will be called. They will not only help you sort out all the difficulties of installing a roofing covering, but will also give a guarantee for their work.a

Old Moscow mansions are covered with seam roofing. This type of roof is strongly associated with architectural classics. However, almost all cottages in classic style, covered with tiles. Perhaps we should return to the well-forgotten old? Moreover, it is not so expensive and looks more stylish.

Roofing sheets that are fastened using the seam method are called pictures. Various metals and alloys are used as material for paintings: copper, aluminum, zinc-titanium, galvanized steel. Copper plating is the most expensive. Zinc-titanium is a more affordable material, but some of its models are more expensive than copper, and it behaves capriciously - if installed incorrectly, it can rot. Perhaps the most budget-friendly solution would be a seam roof made of aluminum with a polymer coating and a film that protects the sheets from scratches. Galvanized steel sheets are also suitable for our climate. They can be coated with polyester and plastisol. This steel can withstand heavy loads, repels dirt well and resists temperature changes. Zinc-titanium actually includes copper, so it can develop a patina over time. But there is a type of material that is covered with a protective transparent film and is intended for any climatic conditions. When ordering non-oxidized copper seam roofing, you need to consider that over time, the natural process of oxidation will cause your roof to turn green. Modern technologies allow you to delay this moment and achieve uniform “greening”, but one way or another, patina is inevitable. Will it match the color of your home? Think about the consequences in advance. Copper is a material that demands respect. When installing it, workers must wear rubber shoes to avoid leaving scratches on the sheets.

“Pictures” are cut to fit the shape of your roof. Rolled metal, unlike popular metal tiles, softerly bends around domed sections of the roof, the tops of turrets, and bay windows. There is a fold along the edges of the picture sheet, which serves as a fastener to the adjacent sheet. The connection of folds can be recumbent single and double, as well as standing corner, when two sheets are connected and bent at an angle of 90C, and double, when the edges are bent at 180C, forming a straight ridge seam. The latter option is more reliable, as it eliminates leaks. There are also self-locking connections. The folds on the sheets are made in production, and they are joined on site using a special device. To fasten paintings to the base of the roof, clamps are used, which can be movable or fixed. The former are used for a certain sheet length, when we're talking about about the expansion of metal - it is the movable part of the clamp that allows the metal to expand and contract without breaking. For the same purpose (so that the sheet can walk), the seam ridges are not pressed to the end, leaving a small gap. Fixed clamps are also needed, but they are installed in other places. Experts themselves determine where and what fasteners are needed depending on the size and location of the sheets, however, even with professional assembly, the metal can form small waves. This is due to its expansion. Over time, the material will “settle down” and the waves will become less noticeable.

The pie for a seam roof is not much different from the pie for metal tiles - it’s still the same lathing, the pitch of which depends on the angle of inclination. However, there are still nuances. For example, a seam roof made of zinc-titanium requires good ventilation, otherwise it will quickly rot. There are 2 methods for ventilation: simple and expensive. When simple they make sparse wooden sheathing. But you can also make a continuous sheathing, and lay a special membrane on it. It is necessary to install zinc-titanium at positive temperatures, otherwise it may break. Seam roofs are good because they can be flat, but if the slope angle is less than 14C, then the sheathing under the roof must be continuous. Titanium-zinc roofing runs the risk of rusting in places if the wrong components are used - only materials made of galvanized steel or stainless steel are suitable for such sheets. And with copper you can’t use anything other than stainless steel or the same copper.

Expert opinion

There is a common misconception - seam roofing is noisy. In fact, if there is thermal insulation in the roofing pie, then the problem of sound insulation is also solved. In addition, metal does not have a tile cross-section, which makes it less noisy. It is better to trust roofing installation to professionals who are well familiar with the seam installation method. “Jack of all trades” hardly know in which places movable and in which fixed clamps are needed. They have not heard about the linear expansion of metal, so they are unlikely to make allowances for this during installation, and such an error can lead to rupture of the material.

For added strength metal sheets, longitudinal stiffening ribs are made on them. Such a roof can withstand additional snow load.

Errors when assembling sheets of pictures:

- Loose seams;

- Rupture of sheets due to their constriction;

- Assemblies on metal due to poor fit.

Advantages of seam roofing:

- Absolute tightness (if installed correctly);

- Possibility of hermetically sealing complex roofing shapes;

- The best coating yield is if the roof is almost flat (angle of inclination up to 12C).

Compliance with the technology for installing seam roofing allows you to prevent corrosion of the coating, its deformation and sagging. Properly installed material will serve its owners for many years. We’ll look further at how to properly install a seam roof with your own hands.

Seam roofing: features and advantages

Seam roofing is distinguished by a special installation technology, which creates a reliable seam lock that prevents water leaks. The appearance of the roof is particularly attractive and gives the building an aristocratic and original appearance.

The roof itself consists of separate panels connected to each other using folds. For their manufacture, sheet or rolled steel is used, always galvanized. To increase the durability of the structure, it is treated with a special coating of non-ferrous metals such as copper, aluminum, zinc, pural or plastisor. The most optimal and durable option is copper. Despite the high cost of such a roof, it has an amazing appearance and good performance characteristics.

By connecting roofing sheets together, it is possible to obtain a connection called a seam. There are four types of such connections:

- single type;

- double type;

- standing type;

- recumbent type.

The first option is relevant if the roof slopes are located at an angle of more than fifteen degrees. The second option is particularly waterproof and durable, although its construction will require more material and effort, but the result is worth it. Standing seams are relevant for joining longitudinal strips.

Among the advantages of a seam roof, we note:

- the ability to use various coatings, which give it a unique shade and originality;

- thanks to seam joints, the roof does not leak

- does not require additional mounting holes, so the roof becomes resistant to changes in temperature;

- a variety of installation technologies, materials, variations in laying sheets or rolls, allows you to create an interesting roofing covering that will harmonize with any building;

- the presence of a smooth surface ensures rapid drainage of water and snow;

- due to the fact that the material is quite flexible, such a roof can be installed on any type of roof;

- the light weight of the structure makes it possible not to install a rafter system;

- such a roof is easy to maintain and repair;

- Duration of operation is another important advantage of this type of roof.

When installing a seam roof, you also need to learn about its disadvantages, such as:

- the need for special equipment that greatly simplifies the execution process installation work;

- steel roofing has high thermal conductivity and therefore requires additional insulation;

- the roof needs to be equipped with additional components that reduce its noise performance;

- in order to protect your home during a thunderstorm, it is necessary to install a lightning rod and grounding;

- On a smooth surface, it is necessary to install snow detainers, since avalanches will fall to the ground during heavy snowfalls.

Types and technology of seam roofing

The most durable copper roofing in use, it will serve its owners for more than one hundred and fifty years. Besides, this type the roof has an attractive appearance, as it has a special textured pattern that imitates various materials. However, the cost of such a roof is quite high, although it quite pays off during operation.

Aluminum roofing is lightweight, resistant to corrosion, mechanical damage and various types of loads. The service life of such a roof reaches one hundred years. The cost of such a roof is an order of magnitude lower than a copper one, but the performance characteristics are also at a high level.

Also, seam roofing is made of titanium-zinc coating, which is distinguished by its prestigious appearance, reliability and durability. Besides, distinctive feature this material is high level its plasticity. After a certain period of use, the roof becomes covered with a patina, which makes it even more elite.

The most affordable material for making seam roofing is ordinary metal. The great demand for this type of roofing is explained primarily by the affordable cost of the coating. The service life of this structure reaches 55 years. You can choose the color and appearance become. In addition, the zinc coating protects the roof from corrosion and destruction.

Seam roofing - installation technology

Seam roofing differs not only in the materials from which it is made, but also in the technological aspects of its installation. In the process of making roofs, materials are used in both sheet and roll versions.

Using sheets - classic version, which unfortunately is losing popularity. The main rule of any installation of a seam roof is the creation of special conditions in the attic space that prevent the formation of condensation on the roof, which destroys it.

An innovative way to install a roof is to use roll materials. This installation technology is characterized by the presence of higher quality seams, which are easily installed by specialists.

Among the advantages roll technology installation of a seam roof, we note:

- installation of not only steel sheets, but also material with a polymer layer, which has better performance characteristics;

- the use of a standing double seam, ensuring a high degree of tightness of materials;

- use of technology in various fields installation of the roof, regardless of the roof slope and its shape;

- speed and ease of work, thanks to the mobility of the equipment used in roof installation.

Tool for installing seam roofing

Correct use of the tool during installation work ensures half the service life of the roofing covering. The main tool for constructing a clamp is used in any installation case, both in roll and sheet. There are two types of tools used when rolling the seam:

- mechanical equipment;

- electric type tool.

The first option involves using a set of pliers, which contain two frames that cover the folds. With their help it is possible to create single and double folds.

The electric machine allows you to speed up the work several times, and after rolling, it automatically stops at the final section of the roof.

Also, when installing a seam roof, you will need the following tools:

- hammer;

- pliers;

- metal scissors;

- mallets;

- drills and screwdrivers;

- level and other measuring instruments.

Additional tools used during the roofing installation process depend on the individual characteristics of the building and the method of installation of roofing materials.

Seam roofing: production and installation

To begin work on installing a seam roof, you should choose a sheathing, for the manufacture of which a steel profile, board or wooden beam. The main requirement for the sheathing is its maximum evenness and absence of recesses.

Seam roof installation instructions:

1. Initially, an insulating coating is laid on the surface of the trusses. The presence of light sheathing will ensure sufficient ventilation of the under-roof space. The interval for laying the sheathing is 40 cm.

3. Before installing the sheets, install the eaves part of the roof.

4. Also install a support board on the ridge area. In order for the joints to be evenly spaced on the roof, the first and last sheets should be cut in relation to the dimensions of the roof.

5. Install a continuous boardwalk on the valley.

6. The sheets are aligned with an overlap of 4 cm. To fix the sheets on the eaves area, the top sheathing is used.

7. At the end sections of the roof, the roofing material is fixed using self-tapping screws and washers, between which sealing gaskets are installed.

8. Snow barriers are laid at the joints between roofing sheets. To perform longitudinal joining of sheets, also use overlap.

Features of installing a copper seam roof

The ridge and ribs on a standing seam roof must be straight. If wood is used to make the sheathing, then do not forget to coat it with an antiseptic composition.

Before starting installation work, you should fix the cornices along the lower edges. Also, drainage system, installed on initial stage. The valleys are fixed on the sheathing, and an anti-condensation film is installed on the rafter system, providing waterproofing.

Before starting work on the roof, measure its slopes. Rectangular slopes should have equal diagonals. When arranging longitudinal joints, the sheets are fixed in the direction from the bottom to the top. If the length of one slope is more than six meters, then it is assembled from several parts.

The sheets are installed with a slight overlap. When installing a copper roof, it is impossible to use a seaming machine, which significantly improves the tightness of the joints between the sheets.

The service life of a copper roof is more than a hundred years, however, in order to ensure that this condition is met, the roof is installed on a continuous deck.

When arranging flooring for a standing seam roof, you should be guided by the following recommendations:

- V mandatory care should be taken to ensure there is a special ventilation gap that allows condensation formed inside the roof to be removed;

- thus, the sheathing prevents corrosion of metal parts and damage to the wooden sheathing;

- the sheathing should help reduce noise generated during rain.

A solid base is also installed if the roof slope is less than fourteen degrees. In order to improve the tightness of the connection between the sheets, after rolling the seams, use silicone sealant.

Installation of a self-latching seam roof

In order to create a self-latching roof, galvanized steel sheets are used. The sheets must be in the form of large canvases, which are connected to each other using special grooves.

The most popular options folds are recumbent and standing versions, used in longitudinal and transverse connections. A self-latching roof is installed much faster and easier than a standard seam roof.

In addition, this type of roofing is distinguished by a variety of color and texture shapes. Therefore, you can choose best option, suitable for a specific building.

To arrange connections between sheets, no special equipment is required, and all work can be carried out independently, without the involvement of specialists. In addition, upon completion of installation, an ideal coating is obtained in the form of a continuous flooring that is absolutely impermeable to moisture.

This roofing option is suitable even for a roof with a slope angle of 8 degrees. Among the advantages of a self-latching roof, we note:

1. Possibility of installation on various types of roofs.

2. Long service life.

3. Thanks to a special installation technology, reliable connections are ensured, and the seams are durable and tight.

4. Seam roofing is characterized by high load-bearing capacity, good resistance to the external environment.

Therefore, when choosing a seam roof for a home that you plan to install yourself, we recommend choosing the self-locking version, since this design does not require the use of special equipment to obtain a high-quality connection between the sheets. Repairing a seam roof will not be difficult, since if certain of its elements are damaged, it is enough to replace them.

Seam roof installation video:

There are many types of different roof coverings. We invite you to discuss what a self-latching metal seam roof is, its design, installation, and how to make it yourself.

What is seam roofing

Modern seam roofing is a type of roof in which roofing materials They are not cut through with nails; they are fastened using special bends of the edges. This type of structure has become widespread in Europe, but at the same time it is still quite rarely used in the CIS countries. The fact is that in case of strong winds or precipitation pressure, the seam may not hold up and begin to leak at certain points. Its production is carried out in almost the same way as profile flooring, with the exception of cutting and rolling.

In addition, the price of work, for example, to repair a seam roof, is quite high compared to other roof structures. Such roofing systems are typically used on roofs that have a slight slope. They are also used for covering a house, constructing domes (“checkers”), or decorating utility rooms: garages, bathhouses, verandas, hangars.

Photo: beautiful checker-shaped seam roof

Photo: beautiful checker-shaped seam roof Design

For a conventional standing seam roof, it is very important minimum slope, it generally varies from 10 degrees to 30. The design of such a roof mainly depends on the seam used. According to SNIP, there are the following types of folds:

- Standing double and single;

- Recumbent double and single.

Lying seams are very convenient for organizing water drainage from the roof. They are connected parallel to the eaves and are suitable for use in regions with high average annual rainfall. Vertical or standing seam seams are characterized by a connection parallel to the rafters. To make a seam roof connection, it is convenient to use a special sheet bending machine, but in most cases the technology is manual, i.e. for roofing works no special equipment needed.

Photo: vertical folds

Photo: vertical folds It is most convenient to build a roof with a single standing seam; this type of construction is called snap-on or lock-on. But at the same time, the most reliable and durable is considered to be a flexible double-seam roof, which is characterized by high levels of tightness of the units.

Seam roofing is galvanized rolled or sheet steel, pre-bent at the edges. Sometimes aluminum is used, but it is too soft and easily deformed, which makes such a surface not durable enough. Metal tiles are used a little less frequently. The steel ready for installation on the roof is called a picture.

Rolls are much more convenient to install; they are simply spread over the roof surface. This material ensures the most airtight connection, thanks to which there is no need to create horizontal folds. Finnish roll tiles with a polymer layer are often used for this.

Seam roofing is also characterized by frequent pitches. Average step frame beams should not exceed 25 centimeters; it is best to work with wood material. At first glance, the result will be a rather heavy rafter system, but the large weight of the beams is compensated by the lightness of the roof itself.

Installation

The right way to start manufacturing a seam roof is to develop drawings. They are useful for calculating sheets and surface size. As you may have noticed from the description of the roof, flashings and gutters are installed after installation, so they do not need to be included in the project. After completing the design work, you need to cut the paintings or measure the length of the rolls.

After this, you need to install the paintings on the sheathing of a standard standing seam roof. This must be done using special profile elements, which are also called clamps. They are attached to the edges of curved pictures. Such a rectangular clamp is inserted with one part under the steel surface, and the other is bent over it. As a result, a strong and reliable seam is formed, which is very cheap compared to installation with screws. The entire process is carried out by a tool for standing seam roofing, which is similar in principle to a manual sheet bending machine. It also bends the ridge and other roof elements if necessary (possible).

It can be purchased from a manufacturer of paintings and folding materials, or rented. Renting will cost several hundred rubles depending on its type and capabilities.

The main advantages of this installation is that the roof is obtained without a hole, i.e. is considered more durable - corrosion will not be able to penetrate solid metal. After roofing work is completed, the painting, like metal siding, simple siding, corrugated sheeting, etc., is coated with a special compound that extends its shelf life.

Photo: snow guards on a seam roof

Photo: snow guards on a seam roof If you need to install funnels for water drainage, a ventilation façade, snow retainers or other additional elements, then you need to make holes in the required ones along the seam roof, after which the work is done. Finally, you will need to cut out the apron to create a hermetically sealed hole.

Despite the materials used and the high tightness of the coating, waterproofing is very important. It must be made from hygroscopic products; polystyrene foam is often used, a little less often mineral wool. The roofing pie of a seam roof generally looks like this:

Scheme: seam roof roofing pie

Scheme: seam roof roofing pie Traditionally, it includes vapor barrier, waterproofing and insulation. It is most convenient to use a film coating as a vapor barrier material, while the insulation should be dense, for example, mineral wool. If you can afford it, you can use penoizol; it will do an excellent job with both of these functions.

Price overview

To buy a seam roof, you need to contact directly the store of the manufacturer of roofing coverings of this type (Ruukki Rannila or Ruukki Classic D Pural, Grand Line, Kalzip and others). In addition, sometimes such coverage is sold on construction markets. There you can find products of such brands as Acrytec, Insi, OMZ (UkrKava plant).

Let's consider what the cost of seam roofing is in various cities of Russia, Belarus and Ukraine:

At the time of purchase, you can choose any roof color. Be sure to check with the manufacturer all the characteristics (GOST material GOST R 52246-2004, width, length, thickness) and guarantees. But in any case, if you want to create a stylish vintage roof or a completely sealed roof, then a seam roof is the most the best option fencing the surface of the house.